0086 15335008985

What types of gases can an fbga mining pneumatic gas butterfly valve safely control?

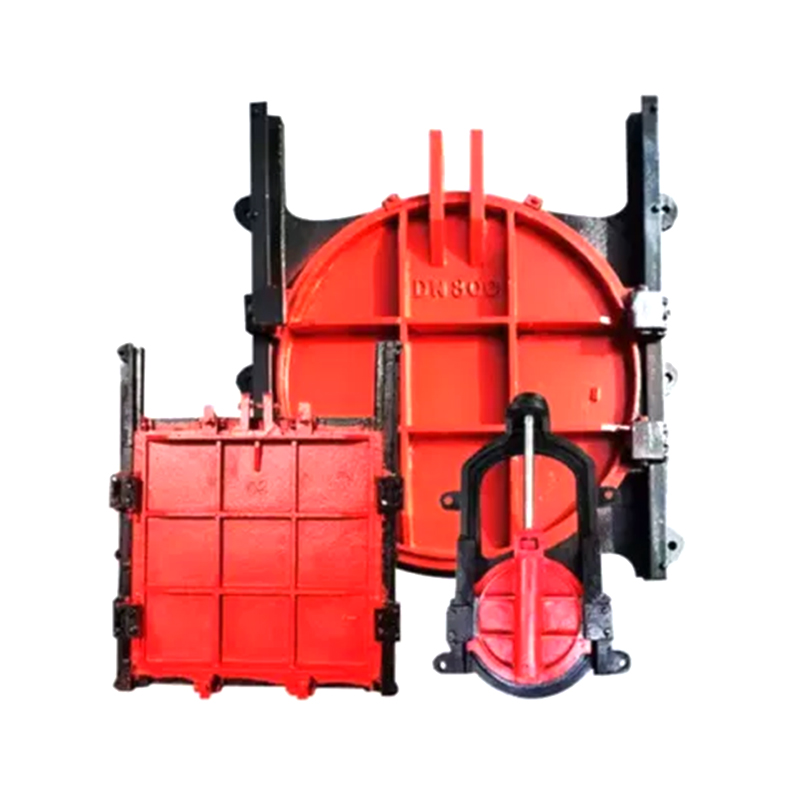

In modern mining operations, gas management is a critical aspect of operational safety, environmental compliance, and process stability. Underground and surface mining environments often involve the presence, generation, or transport of multiple gas types, each with distinct physical behaviors and safety implications. Within this context, the fbga mining pneumatic gas butterfly valve plays a significant role as a flow control and isolation device designed specifically for demanding mining gas applications.

Understanding gas control requirements in mining environments

Mining gas systems differ substantially from conventional industrial gas pipelines. They are shaped by confined spaces, variable flow demands, abrasive contaminants, and strict safety oversight. Gases encountered in mining are not merely process media; they often directly influence worker safety, explosion risk, ventilation efficiency, and equipment reliability.

An fbga mining pneumatic gas butterfly valve is commonly integrated into systems designed for gas regulation, isolation, and emergency shutoff. Its suitability for specific gas types depends on several interrelated factors, including valve body construction, sealing materials, actuator performance, and resistance to environmental stressors. Understanding these requirements is essential before assessing gas compatibility.

Mining gas control typically emphasizes:

- Stable and predictable valve operation under fluctuating flow conditions

- Reliable sealing to prevent unintended leakage

- Resistance to corrosion, moisture, and particulate contamination

- Compatibility with automated or remote control systems

These requirements directly influence which gases can be safely and effectively handled.

Core design characteristics influencing gas compatibility

Before examining individual gas categories, it is necessary to understand the fundamental design characteristics that enable an fbga mining pneumatic gas butterfly valve to manage various gas media.

Valve body and internal geometry

The valve body is typically designed to minimize flow obstruction while maintaining structural integrity under variable pressure and temperature conditions. Smooth internal contours reduce turbulence and prevent localized gas accumulation, which is particularly important in combustible or toxic gas service.

A well-designed internal flow path contributes to predictable gas behavior and reduces the risk of uneven wear, especially in mining systems where gases may carry fine particulate matter.

Sealing system performance

Sealing is central to gas compatibility. Different gases interact differently with sealing materials, particularly in terms of permeability, swelling, and aging behavior. An fbga mining pneumatic gas butterfly valve intended for gas control generally incorporates elastomeric or composite sealing solutions engineered for low leakage and long-term stability.

Effective sealing performance is essential when handling hazardous or oxygen-deficient gases, as even minor leakage can have significant safety implications in confined mining environments.

Pneumatic actuation and control reliability

Pneumatic actuation provides consistent torque and fast response, making it suitable for applications where rapid valve positioning is required. In gas systems, this capability supports precise flow modulation and reliable emergency closure.

The actuator design also influences gas compatibility indirectly by ensuring consistent sealing force across the valve seat under varying operating conditions.

Classification of gases encountered in mining operations

Gases present in mining environments can be broadly classified based on their origin, behavior, and associated risks. Each category places distinct demands on valve performance and material selection.

Ventilation and inert gases

Ventilation systems are fundamental to mining safety. These systems often handle large volumes of non-reactive or low-reactivity gases.

Air and ventilation gas mixtures

Air is the most common gas managed in mining systems. It is used to dilute hazardous gases, regulate temperature, and ensure breathable conditions.

An fbga mining pneumatic gas butterfly valve is well suited for controlling air and ventilation gas mixtures due to:

- Low chemical reactivity with valve materials

- Predictable flow characteristics

- Compatibility with standard sealing materials

Ventilation control is one of the most common applications for this valve type, particularly in main airflow regulation and branch isolation.

Nitrogen and inert gas applications

In certain mining scenarios, inert gases such as nitrogen are introduced for fire prevention or oxygen displacement. These gases are chemically stable and generally compatible with metallic valve bodies and standard sealing materials.

However, inert gas service requires careful attention to leakage control, as unintended oxygen displacement can create hazardous conditions. The low-leakage design of an fbga mining pneumatic gas butterfly valve supports safe inert gas handling when properly specified and maintained.

Combustible gases in mining systems

Combustible gases represent one of the most critical risk categories in mining operations. Valve selection and gas compatibility assessment must be particularly rigorous in these cases.

Methane-rich gas streams

Methane is commonly encountered in underground coal mining and certain hard rock mining environments. It is flammable and can form explosive mixtures with air under specific conditions.

An fbga mining pneumatic gas butterfly valve can be used in methane control systems when designed and installed in accordance with mining safety standards. Key considerations include:

- Tight shutoff capability to prevent leakage

- Anti-static and spark-resistant material selection

- Compatibility with pneumatic control systems located outside hazardous zones

Methane compatibility is not defined solely by the gas itself but by the valve’s overall system integration and maintenance regime.

Mixed combustible gas streams

In some mining processes, methane may be present alongside other hydrocarbons or combustible gas components. These mixed streams require conservative design assumptions.

The ability of an fbga mining pneumatic gas butterfly valve to handle such gases depends on:

- Seal material resistance to hydrocarbon exposure

- Stability of sealing performance over time

- Absence of internal features that could trap gas pockets

Mixed combustible gas control places higher demands on quality control and inspection practices than ventilation gas service.

Toxic and hazardous gases

Mining activities can generate or release gases that pose direct health hazards even at low concentrations.

Carbon monoxide

Carbon monoxide may be produced by incomplete combustion, equipment operation, or underground fires. It is toxic and odorless, making leakage detection particularly challenging.

For carbon monoxide service, an fbga mining pneumatic gas butterfly valve must provide:

- Reliable sealing under continuous operation

- Resistance to gas permeation through sealing materials

- Consistent actuator response during emergency shutdown scenarios

Carbon monoxide control emphasizes fail-safe valve behavior rather than flow modulation precision.

Hydrogen sulfide and similar gases

Certain mining environments may encounter hydrogen sulfide or other sulfur-containing gases. These gases can be corrosive and toxic, placing additional demands on valve materials.

While the fbga mining pneumatic gas butterfly valve can be configured for such service, material selection becomes critical. Corrosion-resistant alloys and compatible sealing compounds are often required to ensure safe long-term operation.

Process and auxiliary gases

Beyond naturally occurring or hazard-related gases, mining operations may also involve auxiliary gas systems.

Compressed air for process support

Compressed air is widely used in mining for tool operation, instrumentation, and control systems. Valves used in these systems must handle dry or slightly moist air with minimal pressure loss.

An fbga mining pneumatic gas butterfly valve is well suited for compressed air control due to its low flow resistance and rapid actuation capability.

Exhaust and waste gas streams

Exhaust gases from engines, generators, or thermal processes may be routed through controlled pathways. These gases can be hot, moisture-laden, and contain particulates.

Compatibility in this context depends on:

- Temperature tolerance of sealing materials

- Resistance to condensation and fouling

- Structural stability under cyclic thermal conditions

Exhaust gas service often requires more frequent inspection and maintenance than ventilation gas control.

Gas compatibility overview table

The following table summarizes typical gas categories and general compatibility considerations for an fbga mining pneumatic gas butterfly valve.

| Gas category | Typical examples | Compatibility considerations | General suitability |

|---|---|---|---|

| Ventilation gases | Air, diluted mixtures | Low reactivity, stable flow | High |

| Inert gases | Nitrogen | Leakage control, safety procedures | High |

| Combustible gases | Methane, mixed hydrocarbons | Tight sealing, anti-static design | Conditional |

| Toxic gases | Carbon monoxide, sulfur gases | Material resistance, fail-safe operation | Conditional |

| Auxiliary gases | Compressed air, exhaust gas | Temperature and moisture tolerance | Moderate to high |

This table is intended as a general reference and does not replace project-specific engineering evaluation.

Material compatibility and gas interaction considerations

The interaction between gas media and valve materials is a determining factor in safe gas control.

Metallic components

Valve bodies and discs are typically manufactured from metals selected for mechanical strength and corrosion resistance. For gas service, surface finish and alloy composition influence long-term performance, particularly when moisture or corrosive components are present.

Metallic compatibility is generally favorable for most mining gases, provided that protective coatings or suitable alloys are used where necessary.

Sealing materials

Sealing materials are more sensitive to gas type. Exposure to certain gases can cause swelling, hardening, or gradual degradation. Selecting sealing compounds appropriate for the intended gas is essential.

Gas compatibility is often limited by seal behavior rather than structural components, making sealing material specification a key design step.

Influence of operating conditions on gas safety

Gas compatibility cannot be evaluated in isolation from operating conditions.

Pressure variation

Mining gas systems may experience fluctuating pressures due to ventilation adjustments or process changes. Valves must maintain sealing integrity across these variations without excessive wear.

Temperature range

Temperature influences gas density, moisture content, and material behavior. While the fbga mining pneumatic gas butterfly valve is designed for typical mining temperature ranges, extreme conditions require careful evaluation.

Presence of contaminants

Dust, moisture, and fine particulates are common in mining gas streams. These contaminants can affect sealing surfaces and actuator mechanisms over time.

Effective gas control depends on managing these environmental factors through design and maintenance, not solely on nominal gas compatibility.

Application-driven gas selection considerations

In practice, gas compatibility decisions are driven by application context rather than gas type alone.

Ventilation control systems

In ventilation applications, the primary concern is stable airflow regulation. The fbga mining pneumatic gas butterfly valve excels in this role due to its predictable flow characteristics and rapid response.

Safety and emergency systems

For emergency isolation or shutdown, gas toxicity and flammability become secondary to fail-safe valve performance and reliability. Actuator configuration and control logic are critical in these scenarios.

Process integration

When integrated into broader process systems, gas compatibility must align with automation requirements, monitoring systems, and maintenance accessibility.

Selection guidance table for typical mining gas applications

The following table provides illustrative guidance linking gas application types to valve selection priorities.

| Application type | Primary gas concern | Key valve priority | Design emphasis |

|---|---|---|---|

| Ventilation control | Air, diluted gases | Flow stability | Disc geometry |

| Fire prevention | Inert gases | Leakage prevention | Seal integrity |

| Hazard gas isolation | Methane, toxic gases | Fail-safe closure | Actuator reliability |

| Process support | Compressed air | Low pressure loss | Internal finish |

This guidance supports preliminary evaluation but should be supplemented with detailed engineering analysis.

Importance of compliance and operational discipline

Safe gas control is not achieved solely through component selection. It also depends on installation quality, inspection routines, and operator training.

An fbga mining pneumatic gas butterfly valve can safely control a wide range of gases when:

- Installed according to defined procedures

- Operated within specified conditions

- Maintained using documented inspection schedules

Operational discipline is as important as technical specification in achieving long-term safety and reliability.

Conclusion

The fbga mining pneumatic gas butterfly valve is capable of safely controlling a broad spectrum of gases commonly encountered in mining environments, including ventilation air, inert gases, certain combustible gases, toxic gases, and auxiliary process gases. Its suitability for each gas type depends on a combination of valve design features, material compatibility, operating conditions, and system integration.

Rather than being defined by a single gas category, safe gas control is achieved through a holistic understanding of how the valve interacts with the gas, the environment, and the operational objectives of the mining system. Careful evaluation and disciplined application allow this valve type to serve as a reliable component in complex mining gas control networks.

Frequently asked questions (FAQ)

What is the most common gas controlled by an fbga mining pneumatic gas butterfly valve?

Ventilation air is the most common gas, as airflow regulation is fundamental to mining safety and environmental control.

Can the valve be used for both ventilation and emergency isolation?

Yes, when properly specified, it can support both continuous control and rapid shutoff functions.

Is special sealing required for combustible gases?

Yes, combustible gas service typically requires sealing materials selected for low permeability and long-term stability.

How does moisture affect gas compatibility?

Moisture can accelerate seal wear and corrosion, making material selection and maintenance particularly important.

Does gas compatibility change over the valve’s service life?

It can, especially if sealing materials degrade. Regular inspection is essential to ensure continued safe operation.

References

- Mining ventilation and gas management engineering literature

- Industrial valve design and gas sealing performance studies

- Occupational safety guidelines related to mining gas control systems

русский

русский Español

Español