How to ensure the safety performance of coal mine valves?

In the mining industry, safety is always the top priority. As a key component in coal mine equipment, the safety performance of coal mine valves is directly related to the life safety of miners, the integrity of production equipment, and the overall safety and stability of mines. Therefore, it is crucial to ensure the safety performance of coal mine valves.

1. Material selection and manufacturing standards

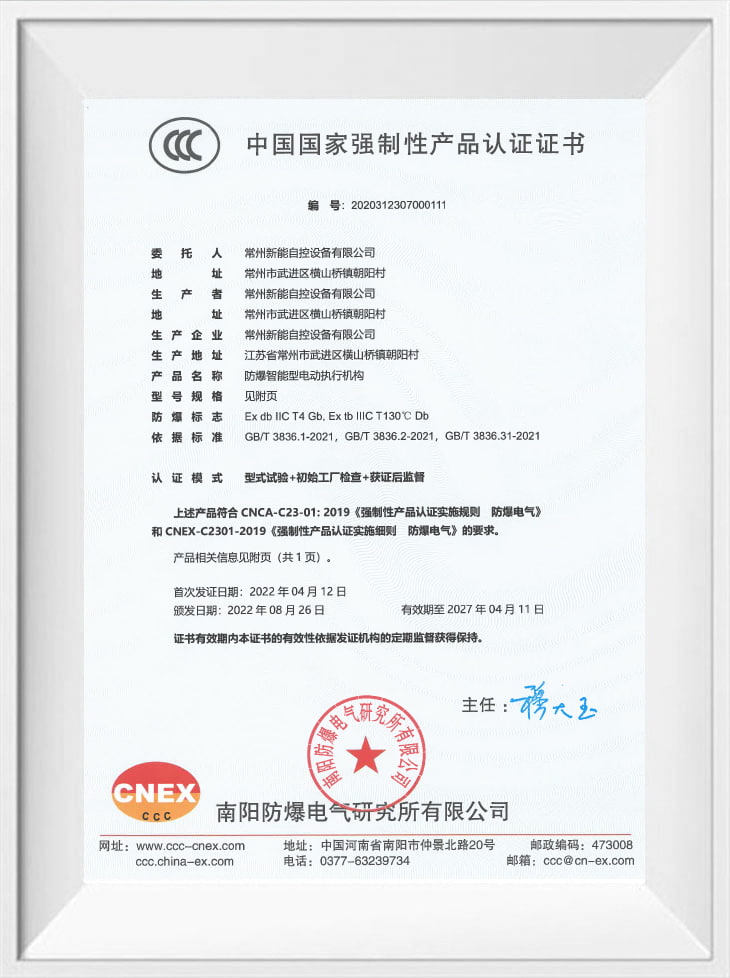

The material selection of coal mine valves must meet the requirements of the mining industry. Due to the complex environment of mines, valves need to withstand high pressure, high humidity, high dust, and possible corrosive media, so high-strength, corrosion-resistant alloy steel or stainless steel is usually used. During the manufacturing process, it must be strictly carried out in accordance with relevant national and industry standards, such as "Technical Conditions for Mining Valves" and "Safety Specifications for Mining Equipment" to ensure the reliability and durability of the valves.

2. Design and testing

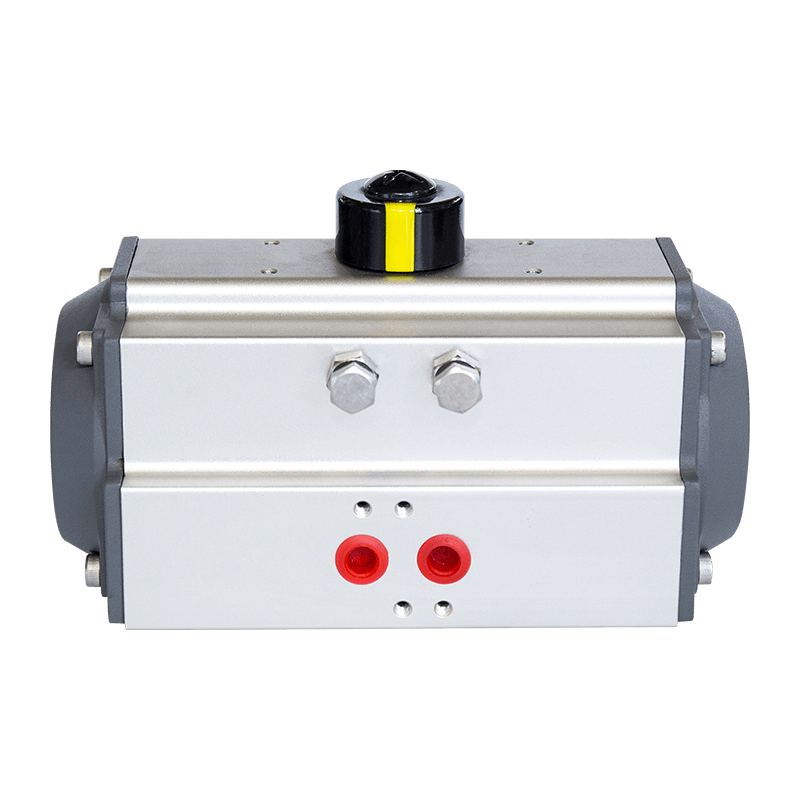

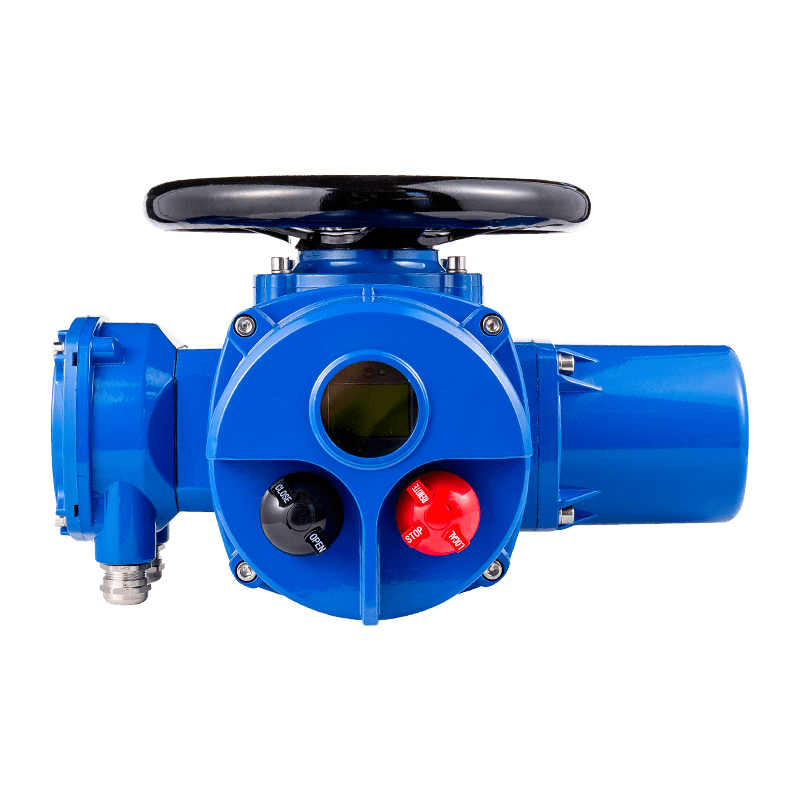

The design of the valve should fully consider the special environment of the mine, including high pressure, impact loads, and possible explosive gases. The design should include strength analysis and pressure resistance testing to ensure that the valve can still work stably under extreme conditions. At the same time, the design should also pay special attention to the sealing performance of the valve to prevent liquid or gas leakage, thereby avoiding threats to mine safety.

After production is completed, coal mine valves must undergo rigorous testing and inspection, including pressure testing, leakage testing and corrosion resistance testing. All test results must comply with relevant standards, such as the "Valve Pressure Test Specification" and the "Valve Leakage Test Standard". These tests ensure the safety and reliability of the valve in actual use.

3. Regular inspection and maintenance

Regular inspection and maintenance of coal mine valves is an important means to ensure their safety performance. The inspection content includes appearance inspection, sealing inspection, opening pressure test and return seat pressure test. Through appearance inspection, it is possible to timely detect whether the valve has corrosion, cracks and other phenomena; sealing inspection ensures that the valve has no leakage under normal working pressure; opening pressure test and return seat pressure test verify whether the valve can be opened and closed quickly and accurately when needed.

In addition to regular inspection, a sound maintenance system should also be established. This includes regular cleaning, lubrication and tightening of the valve to ensure that it is in good condition. For severely worn parts, such as seals, bearings, etc., they should be replaced in time to ensure the sealing and operating stability of the valve.

4. Personnel training and operating specifications

The professional skills and safety awareness of operators are also key factors in ensuring the safety performance of coal mine valves. Enterprises should regularly train operators to familiarize them with the structure, performance and working principle of coal mine valves, and master the correct operating methods and safety precautions. At the same time, detailed operating procedures should be formulated to clarify the opening and closing methods of valves, emergency treatment measures, and regular inspection and maintenance requirements.

During the operation, operators should pay close attention to the operating status of the valves. If abnormal sounds, vibrations, temperature increases, etc. are found, the machine should be stopped immediately for inspection.

русский

русский Español

Español