0086 15335008985

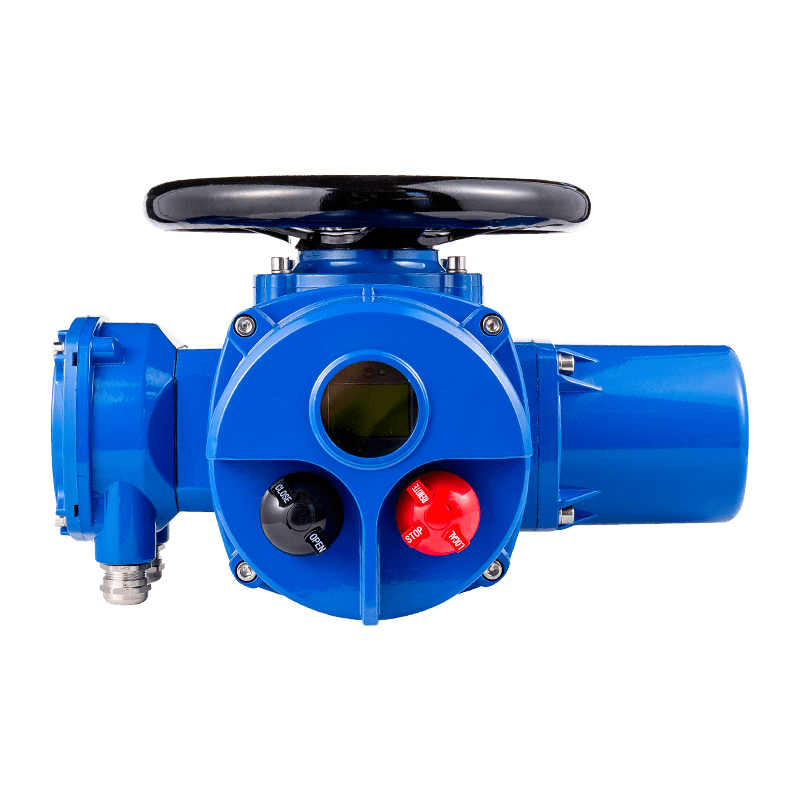

Cat:Quarter Turn Electric Actuator

The QL series of rotary valve electric devices includes ordinary, integral, regulating, intelligent, explosion-proof and...

See Details

In the world of industrial flow control, the seamless integration between an actuator and a valve is paramount for achieving reliable, efficient, and safe operation. The zl series multi-turn valve electric actuator is engineered specifically for a class of valves that require multiple rotations of the stem to transition from fully open to fully closed positions. Understanding the compatibility between this robust actuation solution and various valve types is not merely a technical exercise; it is a fundamental step in designing, maintaining, and optimizing fluid handling systems across countless industries.

The core function of a multi-turn electric actuator is to provide the precise rotational force and control necessary to operate valves that manage the flow of liquids, gases, and slurries. When selecting an actuator, plant managers, engineers, and system designers must consider the specific demands of the valve it will drive. A mismatch can lead to operational failure, premature wear, or even safety hazards. The zl series multi-turn valve electric actuator is designed to meet these challenges, offering a versatile and reliable solution for a wide array of demanding applications. This analysis will serve as a guide for buyers and specifiers in the water treatment, power generation, oil and gas, and chemical processing sectors, among others, who are evaluating this actuator for their projects.

At its heart, the compatibility of the zl series multi-turn valve electric actuator with a specific valve is determined by the valve’s stem operation and the torque/thrust required to cycle it. Multi-turn valves, as the name implies, need their stem to be rotated numerous times—often ranging from a few dozen to several hundred turns—to move the obturator (the closing element) from one extreme position to the other. This is in stark contrast to quarter-turn valves, which require only a 90-degree rotation. The zl series multi-turn valve electric actuator is equipped with a robust gearbox and an electric motor that work in concert to generate the high output torque necessary for this multi-turn operation while managing the relatively low speed of travel for the valve stem.

The key mechanical interface is the actuator-to-valve coupling. This component is critical for transferring the torque and thrust from the actuator to the valve stem. The design of this coupling must account for alignment, potential side loads, and the transmission of force without slippage or damage. For the zl series multi-turn valve electric actuator, these couplings are engineered to create a secure and reliable connection with standardized valve stem designs. Furthermore, the thrust capacity of the actuator is a crucial consideration, particularly for valves where the stem rises (as in rising stem gate valves), as the actuator must be capable of absorbing the axial force generated during operation. Understanding this fundamental principle is the first step in appreciating the specific compatibilities discussed in the following sections.

Gate valves represent one of the most common and fundamental applications for the zl series multi-turn valve electric actuator. These valves are primarily designed for isolation duty, providing a tight seal in the fully open or fully closed position. They are not typically used for flow throttling. The operation of a gate valve involves rotating the stem, which, through a threaded mechanism, lifts or lowers a solid gate (a wedge or parallel disc) into or out of the flow path. This linear motion requires a significant number of turns, making it an ideal match for a multi-turn electric actuator.

The compatibility between a zl series multi-turn valve electric actuator and a gate valve hinges on several factors. The most critical is torque requirement. The actuator must generate enough torque to overcome the static friction to unseat the gate (breakaway torque), the dynamic friction as it moves (running torque), and finally, the force required to seat it tightly again at the end of the stroke (seat torque). The zl series is designed with a torque profile that exceeds these requirements for a wide range of gate valve sizes and pressure classes. For rising stem gate valves, the actuator must also accommodate the axial thrust as the stem extends, a feature that is integral to the design of the zl series multi-turn valve electric actuator. This makes it a suitable gate valve actuator for critical isolation points in pipelines carrying water, oil, gas, and other media. Its IP67/IP68 protection rating ensures reliable performance in buried or submerged applications, a common scenario for pipeline gate valves.

While gate valves are for on/off service, globe valves are specifically designed for flow regulation and throttling. Their distinct spherical body shape houses a plug-type disc that moves linearly onto a seat, usually parallel to the flow direction. This design allows for precise control over the flow rate with minimal wire-drawing or erosion of the disc and seat. The operation of a globe valve is inherently multi-turn, as the stem must be threaded in or out to position the disc accurately at any point between open and closed.

Integrating a zl series multi-turn valve electric actuator with a globe valve unlocks advanced process control capabilities. The actuator’s ability to provide modulating control is essential here. Unlike a simple on/off operation, the zl series multi-turn valve electric actuator can be equipped with proportional control signals (e.g., 4-20 mA) and a positioning circuit to hold the valve at any intermediate position as dictated by a process controller. This is vital for applications in heating, ventilation, and air conditioning (HVAC) systems for temperature control, in fuel supply lines, or in chemical feed systems where precise flow rates are mandatory. The robust construction of the actuator ensures that it can handle the high stem forces often encountered in globe valves, especially in high-pressure drop applications. The compatibility extends to various disc and seat trims, making the zl series multi-turn valve electric actuator a versatile control valve actuator solution.

Diaphragm valves occupy a unique niche in the valve world, characterized by their use of a flexible diaphragm that acts as the obturator. When the actuator turns the stem, it compresses the diaphragm against a weir or saddle, thereby shutting off the flow. This design creates a leak-tight seal and, most importantly, isolates the valve stem and bonnet assembly from the process fluid. This makes them exceptionally well-suited for handling corrosive, abrasive, or viscous media, as well as sterile fluids in the pharmaceutical and food & beverage industries.

The zl series multi-turn valve electric actuator is a highly compatible driving force for diaphragm valves. The multi-turn action is required to apply the compressive force needed to deform the diaphragm effectively onto the weir. The torque output of the actuator must be sufficient to ensure a tight seal without over-compressing and prematurely fatiguing the diaphragm. The inherent duty cycle of the zl series multi-turn valve electric actuator is well-matched to the typical operation of diaphragm valves, which are often used for on/off and throttling duties in batch processes. Furthermore, the non-rotating, linear stem movement of many diaphragm valve designs aligns perfectly with the thrust-bearing capability of the actuator. This compatibility makes the electric actuation of diaphragm valves in water treatment plants for chemical dosing or in mining and mineral processing for slurry handling a reliable and maintenance-friendly solution.

The term sluice valve is often used interchangeably with gate valve in water distribution contexts, typically referring to large-sized gate valves used for isolation in canals, pipelines, and water treatment works. Similarly, weir valves are a type of diaphragm valve with a specific saddle design. The compatibility of the zl series multi-turn valve electric actuator with these valves reinforces its position in the water and wastewater industry.

For large sluice valves, the torque requirements can be substantial, especially when installed in dirty water where sediment can partially block the gate. The zl series multi-turn valve electric actuator is built to deliver high torque outputs, ensuring reliable operation even under demanding conditions. Its robust construction and environmental protection make it suitable for installation in valve pits and other challenging locations common in water infrastructure. For weir valves, the considerations are similar to those for standard diaphragm valves, with the actuator providing the controlled force needed to achieve a bubble-tight seal across the weir. The availability of manual override features in the zl series multi-turn valve electric actuator is a critical safety and operational feature for these applications, allowing for manual control during maintenance or power outages.

While valve type is the primary determinant of compatibility, several other critical factors must be considered to ensure a successful integration of the zl series multi-turn valve electric actuator.

Torque and Thrust Requirements: This is the most crucial specification. The required torque for the valve (breakaway, running, and seat) must be less than the rated output torque of the actuator. Similarly, for rising stem valves, the actuator’s thrust capacity must not be exceeded.

Control and Feedback Requirements: The operational need dictates the control package. A basic on/off control with limit switches is sufficient for isolation valves. For throttling applications, a modulating control with a precision potentiometer or absolute encoder is necessary. The zl series multi-turn valve electric actuator can be configured with these options to provide the required position feedback (4-20 mA or digital signal) to the control system.

Environmental and Operational Conditions: The actuator’s ingress protection (IP) rating, temperature range, and hazardous area certifications (if applicable) must be suitable for the installation location. Operating in an explosive atmosphere requires a specially certified actuator.

The following table summarizes the primary valve types and their key compatibility points with the zl series multi-turn valve electric actuator:

| Valve Type | Primary Function | Key Compatibility Considerations with zl series actuator |

|---|---|---|

| Gate Valve | Isolation (On/Off) | High breakaway torque, thrust capacity for rising stem, duty cycle for infrequent operation. |

| Globe Valve | Throttling / Regulation | Modulating control capability, precise positioning, ability to handle high stem forces. |

| Diaphragm Valve | On/Off & Throttling of Corrosive/Slurry Media | Controlled torque to avoid diaphragm fatigue, compatibility with linear stem thrust. |

| Sluice Valve | Isolation in Water Systems | Very high torque output, robust construction for harsh, submerged, or buried environments. |

The zl series multi-turn valve electric actuator demonstrates extensive compatibility with a wide range of multi-turn valves, making it a versatile and indispensable component in modern industrial automation. Its design is precisely aligned with the operational demands of gate valves, globe valves, diaphragm valves, and specialized sluice and weir valves. By providing the necessary torque, thrust, and control capabilities, it enables reliable, efficient, and safe operation across critical sectors like water management, power generation, and chemical processing.

The decision to employ a zl series multi-turn valve electric actuator should be based on a thorough analysis of the valve’s specific requirements, including its torque-thrust profile, operational duty cycle, and the necessary level of control integration. When these factors are correctly matched, the result is a robust and long-lasting actuation solution that enhances system performance and reduces total cost of ownership. For engineers, specifiers, and buyers seeking a reliable electric valve actuator for multi-turn applications, the compatibility of the zl series with such a broad spectrum of valve types presents a compelling and technically sound choice.