0086 15335008985

What materials and sealing technologies are used to ensure long-term durability in the QC Series Partial Rotary Electric Actuator?

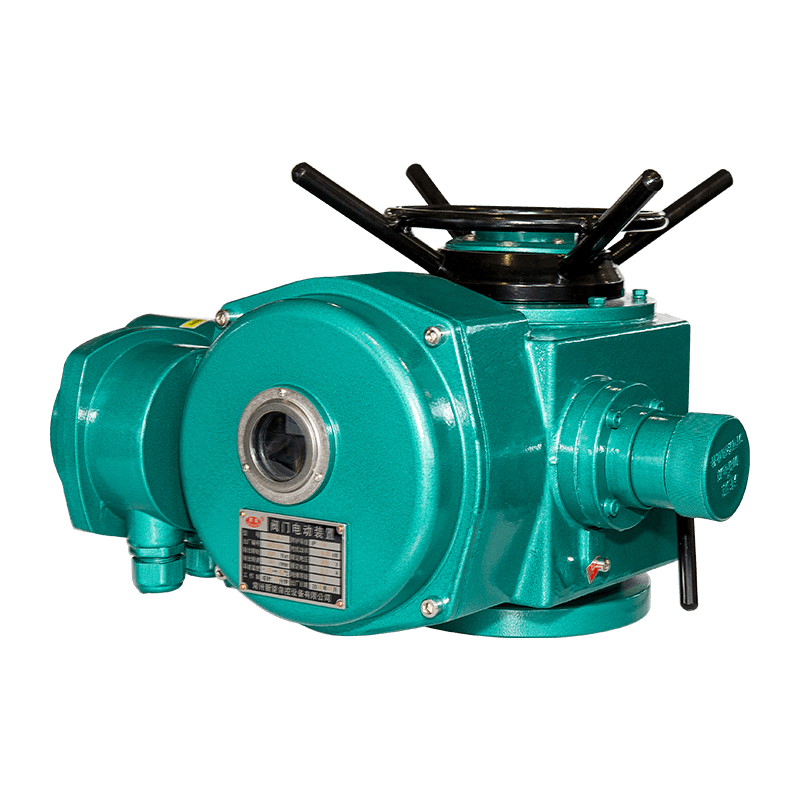

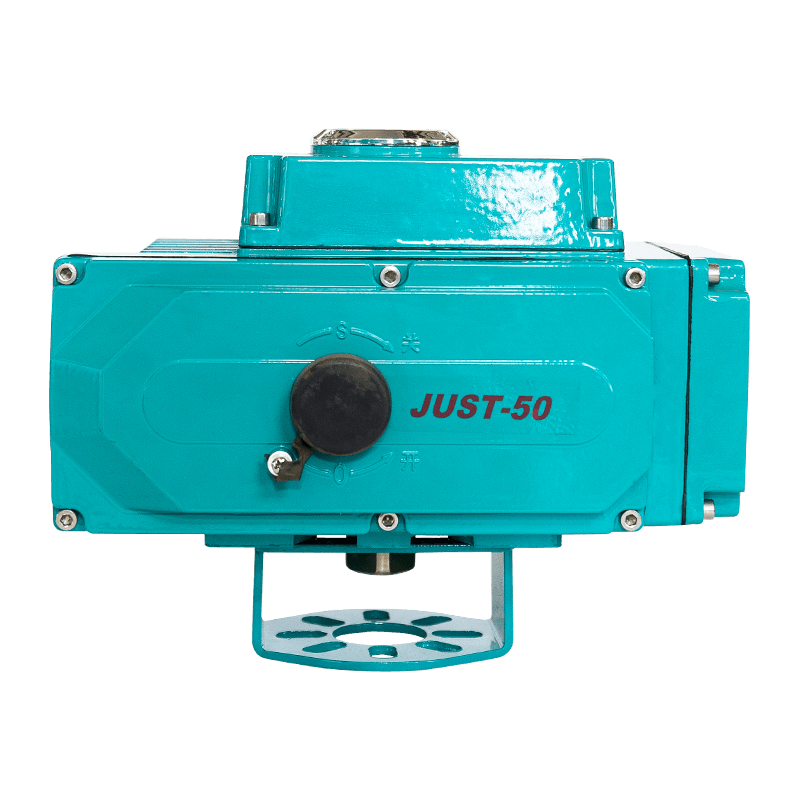

The QC Series Partial Rotary Electric Actuator has become an essential component in modern industrial automation, providing reliable performance for various valve types in multiple sectors. One of the critical factors contributing to its durability and long-term reliability is the selection of materials and the implementation of advanced sealing technologies.

Importance of material selection in the QC Series Partial Rotary Electric Actuator

The durability of any electric actuator is highly dependent on the materials used in its construction. The QC Series Partial Rotary Electric Actuator is designed to withstand continuous operation in demanding environments, which requires careful consideration of both mechanical and environmental stresses.

Key aspects of material selection include:

- Structural strength: Actuator housings and internal components must withstand operational torque and mechanical loads without deformation.

- Corrosion resistance: Industrial applications often involve exposure to water, chemicals, or corrosive gases. Selecting materials that resist corrosion ensures long-term reliability.

- Wear resistance: Moving parts within the actuator, such as gears and shafts, must resist wear to maintain precision over thousands of operational cycles.

Commonly, high-quality aluminum alloys, stainless steel, and engineered polymers are used in the QC Series Partial Rotary Electric Actuator. Aluminum alloys provide an excellent strength-to-weight ratio while maintaining corrosion resistance. Stainless steel is often utilized for shafts and internal components subjected to high stress, ensuring minimal wear and extending service life. Engineered polymers are typically used in non-load-bearing components, offering low friction and self-lubrication benefits.

Housing materials and corrosion protection

The actuator housing is the first line of defense against environmental hazards. The QC Series Partial Rotary Electric Actuator housing is designed to endure exposure to moisture, dust, and industrial chemicals.

Aluminum alloys and surface treatments

Most housings are made from high-grade aluminum alloys, which provide rigidity and lightweight characteristics. To enhance corrosion resistance, these housings undergo surface treatments such as anodizing or powder coating. Anodizing creates a hard, protective oxide layer on the aluminum surface, preventing corrosion in harsh conditions. Powder coating provides an additional protective barrier, particularly in outdoor or humid environments.

Stainless steel components

For applications where corrosion risk is higher, such as chemical plants or marine environments, stainless steel components are incorporated into the housing and internal mechanical parts. Stainless steel’s inherent resistance to oxidation ensures that actuator performance remains stable over time.

Sealed enclosures

The QC Series Partial Rotary Electric Actuator often features sealed housings with specific IP (Ingress Protection) ratings. These enclosures prevent water and dust ingress, protecting internal electrical and mechanical components. IP66 or IP67 ratings are common, ensuring the actuator can operate reliably in outdoor and industrial environments.

Internal mechanical components and material selection

Internal components such as gears, shafts, bearings, and couplings are essential to the QC Series Partial Rotary Electric Actuator’s function. The materials used for these parts determine operational smoothness, torque accuracy, and lifespan.

- Gears: Typically manufactured from hardened steel or high-strength alloys to resist deformation under load. Surface treatments, including case hardening, reduce wear and friction.

- Shafts: Stainless steel or alloy steel shafts maintain precision alignment and resist bending or fatigue. Shafts are often polished to reduce friction with bearings and seals.

- Bearings: Bearings play a critical role in rotational stability. High-grade ball or roller bearings ensure smooth operation and distribute mechanical load efficiently.

- Couplings and linkages: Components that transfer motion from the motor to the valve are made from materials that balance strength with some elasticity to absorb torque spikes and reduce wear.

Electrical components and thermal management

While primarily focused on mechanical durability, the QC Series Partial Rotary Electric Actuator also integrates electrical components that influence long-term performance.

- Motor materials: Motors often use copper windings and laminated steel cores to maximize efficiency and minimize heat generation.

- Insulation materials: High-quality insulation prevents electrical failure due to thermal stress or moisture. Materials like polyimide or epoxy resins are common in actuator motor assemblies.

- Thermal management: Aluminum housings and internal heat sinks dissipate heat, reducing the risk of overheating and material degradation over time.

Sealing technologies in the QC Series Partial Rotary Electric Actuator

Sealing technologies are crucial in ensuring the QC Series Partial Rotary Electric Actuator maintains its integrity under harsh conditions. These seals protect internal components from dust, moisture, chemicals, and mechanical wear, directly impacting durability and operational reliability.

Types of seals

-

O-rings and gaskets:

- O-rings made from viton, EPDM, or silicone are used around rotating and static interfaces to prevent fluid or dust ingress.

- Gaskets are often placed between housing components to provide a robust seal for external enclosure openings.

-

Lip seals and rotary seals:

- Lip seals are utilized around rotating shafts, providing a tight barrier against contaminants while minimizing friction.

- These seals are made from durable elastomers or PTFE-based compounds that resist wear and chemical attack.

-

Double or redundant sealing:

- In applications requiring higher reliability, the QC Series Partial Rotary Electric Actuator uses double-sealing configurations, where a primary seal prevents ingress and a secondary seal serves as a backup.

Seal placement and design

Proper seal placement ensures both electrical and mechanical components remain protected. Seals are strategically positioned at:

- Motor shafts and output shafts

- Housing joints and cover interfaces

- Points of interface with actuated valves

Advanced designs incorporate seals that maintain consistent pressure contact on moving surfaces, compensating for thermal expansion and mechanical tolerances.

Material selection for seals

- Viton: High-temperature resistance, chemical stability

- EPDM: Excellent water and ozone resistance

- Silicone: Flexible and maintains sealing under extreme temperature ranges

- PTFE: Chemically inert, low friction, ideal for high-speed shafts

Selecting the appropriate seal material based on application conditions ensures that the actuator can operate reliably without premature failure.

Environmental resistance and durability

The combination of high-quality materials and advanced sealing technologies allows the QC Series Partial Rotary Electric Actuator to perform reliably in environments that would compromise lesser actuators. Key durability considerations include:

- Temperature extremes: Material selection and sealing technologies ensure actuator components do not degrade under high or low temperatures.

- Chemical exposure: Actuators installed in chemical plants or wastewater facilities resist corrosion from aggressive media.

- Moisture and dust: High IP-rated enclosures and precision seals protect against water ingress and particulate contamination.

- Mechanical stress: Hardened gears, alloy shafts, and reinforced housings resist deformation and wear from continuous operation.

Maintenance considerations for long-term durability

Even with robust materials and seals, periodic maintenance is essential to extend the life of the QC Series Partial Rotary Electric Actuator. Recommended practices include:

- Visual inspection: Checking for signs of wear, corrosion, or seal degradation

- Lubrication: Ensuring moving components and gears are properly lubricated according to manufacturer recommendations

- Seal replacement: Periodically replacing O-rings, gaskets, and rotary seals to maintain protection against ingress

- Electrical checks: Confirming insulation integrity and motor function to prevent thermal or mechanical damage

Maintenance strategies ensure that the actuator maintains performance and reduces unplanned downtime, particularly in critical industrial processes.

Application-specific considerations

The durability of the QC Series Partial Rotary Electric Actuator can vary depending on application requirements. Buyers and engineers often consider:

- Outdoor installations: Require UV-resistant materials, high IP-rated enclosures, and corrosion-resistant metals

- Marine environments: Stainless steel and specialized coatings protect against saltwater corrosion

- Chemical processing: Seal materials must resist aggressive chemicals, and housings may require secondary protective coatings

- High-cycle operations: Hardened gears and durable bearings are critical for long-term reliability

Matching the actuator materials and sealing solutions to the application environment maximizes operational lifespan and reduces maintenance costs.

Comparative overview of materials and seals

| Component | Typical Material | Purpose/Benefit | Notes |

|---|---|---|---|

| Housing | Aluminum alloy, stainless steel | Structural strength, corrosion resistance | Surface treatments enhance protection |

| Internal gears | Hardened steel | High torque, wear resistance | Case hardened for long life |

| Shaft | Stainless steel | Precision, fatigue resistance | Polished for reduced friction |

| Bearings | Ball/roller bearings | Smooth rotation, load distribution | High-grade alloys |

| O-rings/gaskets | Viton, EPDM, silicone | Fluid and dust sealing | Selected based on chemical/temperature requirements |

| Lip/rotary seals | PTFE, high-performance elastomers | Shaft sealing, low friction | Resistant to wear and chemical attack |

| Motor windings/insulation | Copper, epoxy/polyimide | Electrical efficiency, heat resistance | Ensures long-term reliability |

This table illustrates the synergy between materials and sealing technologies, emphasizing how design choices influence durability and performance.

Conclusion

The long-term durability of the QC Series Partial Rotary Electric Actuator is a direct result of careful material selection and advanced sealing technologies. From aluminum alloy housings and stainless steel shafts to O-rings, lip seals, and PTFE-based rotary seals, each component is engineered to withstand mechanical, thermal, and chemical stresses.

By combining robust structural materials, precision-engineered internal components, and reliable sealing solutions, the QC Series Partial Rotary Electric Actuator achieves operational longevity across a variety of industrial applications.

The integration of high-quality materials and advanced sealing technologies, along with proactive maintenance, ensures that the QC Series Partial Rotary Electric Actuator continues to meet the demands of modern automation systems, offering both reliability and efficiency.

русский

русский Español

Español