0086 15335008985

Technical Characteristics and Application Analysis of Electric Flange Ball Valve

Working principle analysis

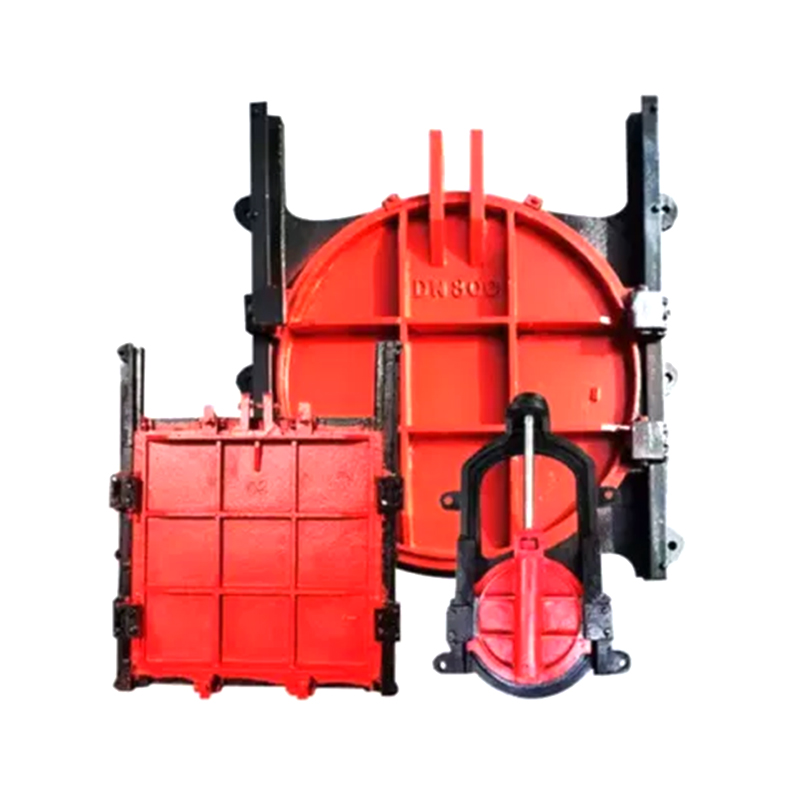

The electric flange ball valve has a unique operating mechanism, the core of which is to have the same 90-degree rotation and lifting action. On its axis, there is a circular through hole or channel, which is a very important structure. As a key component, the ratio of the spherical surface to the channel opening is carefully designed. When the sphere rotates 90 degrees, the inlet and outlet will present a spherical state, thereby effectively cutting off the flow of the medium. When the passage needs to be opened, the sphere is rotated in the opposite direction to align the circular through hole with the pipeline, so that the medium can pass smoothly. Only 90 degrees of rotation is required, and the valve can be tightly closed under the action of a small torque. The completely equal inner cavity of the valve body builds an ideal low-resistance, straight-through channel for the flow of the medium, reducing energy loss.

Functional characteristics display

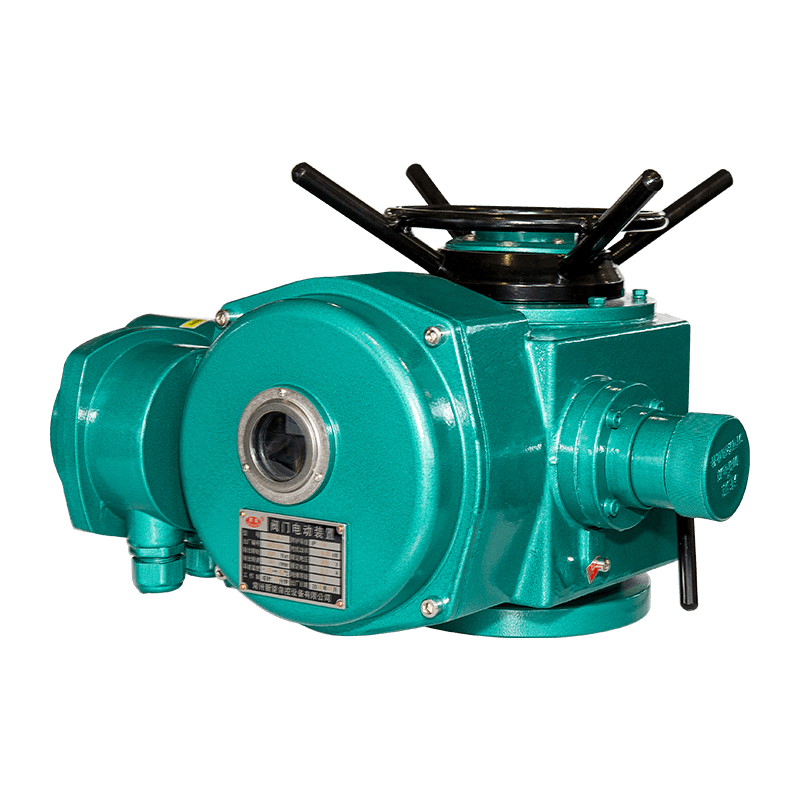

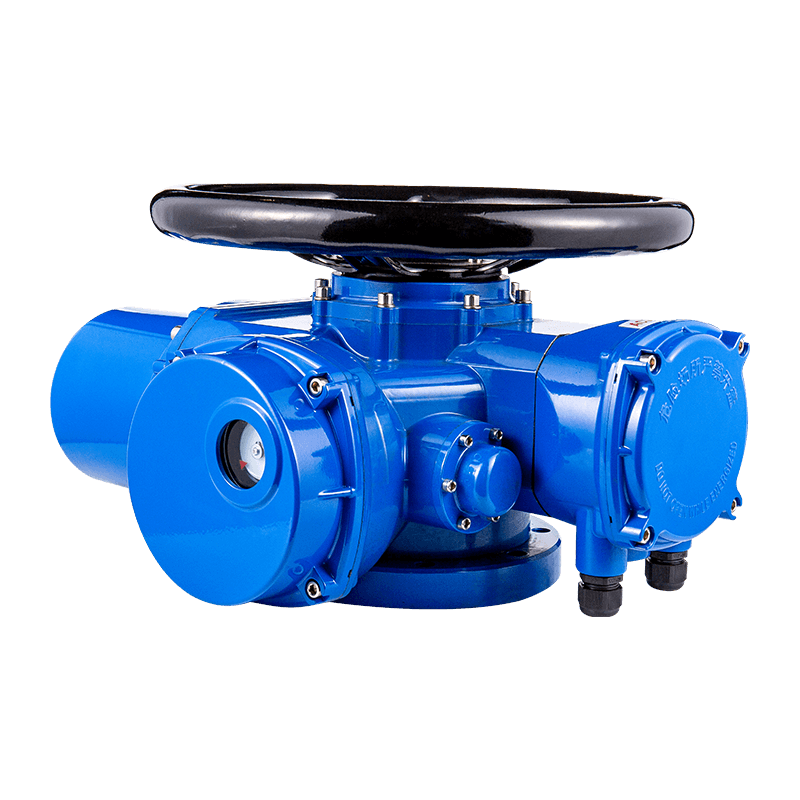

Ball valves are generally considered to be suitable for directly opening and closing pipelines to achieve control of the on-off of the medium. The electric flange ball valve performs excellently in this basic function, and can quickly and accurately cut off or connect the medium in the pipeline, providing a solid guarantee for the stable operation of various industrial processes. With the continuous advancement of technology and the continuous evolution of industry needs, the functions of ball valves have also been expanded, and electric flange ball valves are now also designed to have throttling and flow control functions. By precisely controlling the electric actuator and adjusting the rotation angle of the ball, the valve opening can be flexibly changed, thereby accurately regulating the flow of the fluid and meeting the needs of refined flow management under complex working conditions.

Product Significant Features

The electric flange ball valve has a compact overall structure and a small footprint, which has significant advantages in installation environments with limited space. It can be easily adapted to dense industrial plants and building facilities with strict requirements on space layout, bringing great convenience to engineering design and installation. The operation process is simple and easy to understand. With the help of electric actuators, operators can easily open, close and adjust the valve remotely without having to go to the site for manual operation, saving labor costs and operation time. The maintenance of this product is also relatively convenient. The structure of each component is clear, easy to disassemble and assemble, and can be quickly checked and repaired in case of failure, reducing equipment downtime and improving production efficiency. In terms of general working media, electric flange ball valves can operate stably and reliably realize the transportation and control of media. In the face of highly oxidizing oxygen, highly corrosive hydrogen peroxide, and flammable and explosive methane and ethylene, special materials and sealing structures are used to effectively resist the erosion of the medium and ensure long-term stable operation under complex and dangerous working conditions.

Valve body structure

The electric flange ball valve with an integral valve body has a strong structural integrity and is obtained by one-time molding or integral processing during the manufacturing process. This valve body has no gaps or splicing, has excellent strength and sealing, can withstand high pressure, and effectively avoids medium leakage. In some occasions with extremely high requirements for sealing performance and large pressure fluctuations, such as high-pressure gas transmission pipelines and high-purity liquid transmission systems, electric flange ball valves with integral valve bodies are widely used. The modular valve body is composed of multiple independent modules, and each module can be flexibly designed and manufactured according to different usage requirements. This design makes the valve more convenient when assembling, repairing and replacing parts. When a module fails, only the module needs to be replaced in a targeted manner, without large-scale disassembly and repair of the entire valve, shortening the repair time and reducing maintenance costs. In projects that require frequent adjustments and upgrades to valves, the advantages of modular valve bodies are particularly prominent, and can better adapt to engineering needs at different stages.

русский

русский Español

Español