0086 15335008985

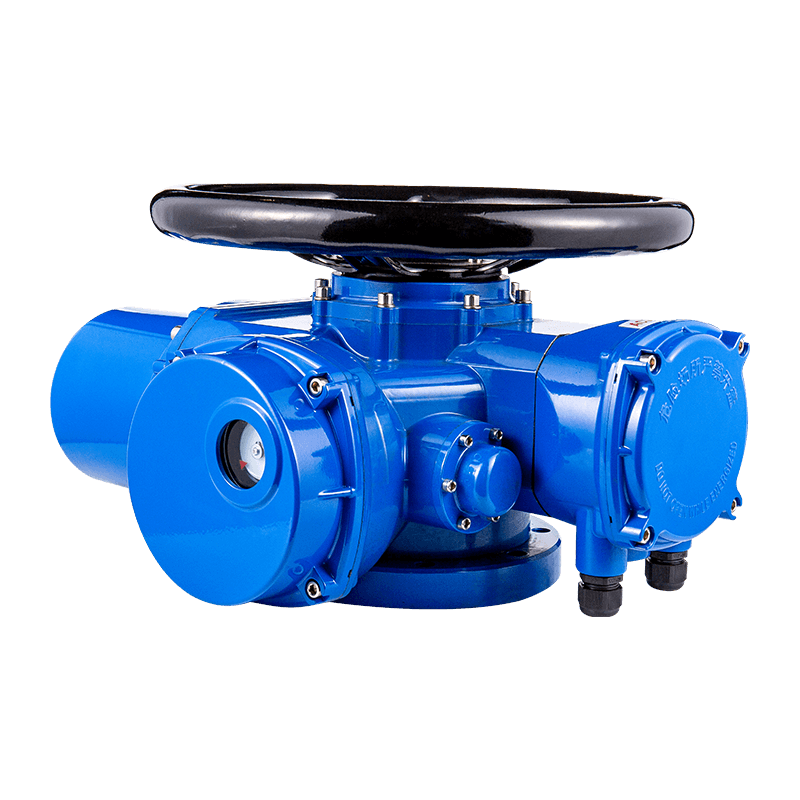

Explosion-Proof Electric Butterfly Valve: The Core of Safety Control in Mining Operations

In coal mines, metal mines and other mining environments, flammable and explosive gases coexist with corrosive media, which places extremely high demands on the safety and adaptability of equipment. As a control device designed specifically for such scenarios, the explosion-proof electric butterfly valve has become an indispensable key component in the mine fluid system with its unique structural design and performance advantages, meeting the needs of automated control.

Cooperative design of special materials and structures

The core competitiveness of explosion-proof electric butterfly valves begins with the scientific ratio of materials and structures. The main components such as the valve body and butterfly plate are mostly made of cast steel, stainless steel or alloy steel. These materials not only have sufficient mechanical strength to withstand the high pressure of mine pipelines, but also can resist long-term erosion by corrosive media such as water, sulfur-containing gases, acid and alkali solutions. The butterfly plate adopts an eccentric or midline design, combined with elastic seals, which reduces the resistance of the medium flow while ensuring the sealing performance, and adapts to the control needs of different media such as water pipelines and gas pipelines in mines. The connection part between the electric actuator and the valve body has been specially treated to ensure that the structure can remain stable during frequent operations and avoid safety hazards caused by mechanical wear.

Safe fusion of explosion-proof and electric functions

Explosion-proof performance is the foundation for this type of valve to gain a foothold in the mining environment. Its design strictly follows international and national standards such as API, ISO, and GB. The circuit system of the actuator is encapsulated in a flameproof shell, and the electric sparks of the internal components are confined inside the shell to prevent contact with flammable and explosive gases from the outside. At the same time, the electric drive method realizes remote control, and the operator can complete the opening and closing of the valve and flow adjustment without entering the dangerous area, improving operating efficiency and fundamentally avoiding the safety risks that may be caused by human operation. This combination of "explosion-proof + electric" allows the valve to meet the needs of automated production while building a solid safety barrier for mining operations.

Performance advantages that adapt to multiple scenarios

The diversity of mining environments requires valves to have a wide range of adaptability. The pressure and temperature application range of the explosion-proof electric butterfly valve has been optimized to cope with the differences in working conditions in different mines. Whether it is low-temperature freezing medium transportation or high-temperature steam pipeline control, it can maintain stable performance. Its drive system supports flexible switching between manual and electric. In emergencies such as power outages, the system can be maintained through manual operation to ensure the continuity of the mine fluid system. The corrosion resistance of the valve enables it to work for a long time in complex media such as sulfur-containing gases and slurries, reducing failures caused by material degradation and reducing maintenance frequency.

Long-term guarantee of maintenance and standards

In order to extend the service life and maintain safety performance, explosion-proof electric butterfly valves require regular maintenance. Daily inspections include the wear of the sealing surface, the operating sound of the electric actuator, the integrity of the explosion-proof housing, etc. Timely replacement of aging seals or adjustment of the parameters of the actuator can prevent small faults from evolving into system risks. These maintenance tasks do not exist in isolation, but complement the manufacturing standards of the valves. From raw material selection to finished product testing, each process is based on relevant standards to ensure that the valve has the quality that meets the safety requirements of the mine when it leaves the factory, and regular maintenance is the long-term continuation of this quality, ultimately achieving safe symbiosis between equipment and mine operations. The design concept of the explosion-proof electric butterfly valve is to integrate safety, adaptability and automation requirements, and to cope with the multiple challenges of the mining environment through the coordination of materials, structures and functions.

русский

русский Español

Español