0086 15335008985

How Does a Coal Mine Control Box Ensure Safety and Efficiency?

The extraction of coal remains a fundamental activity for energy production and industrial processes in many parts of the world. This operation, conducted in one of the most challenging and hazardous environments known to industry, demands an extraordinary level of control, monitoring, and safety assurance. At the heart of this complex web of machinery and protocols lies a critical piece of equipment: the coal mine control box. This unit is not a singular device but rather an integrated assembly of components designed to manage, regulate, and protect the various systems operating within a mine. Its role is pivotal in transforming raw electrical power and control signals into the safe, orderly, and efficient operation of equipment that ranges from conveyor belts and ventilation fans to pumps and cutting machinery. Understanding the design, function, and critical importance of this equipment is essential for appreciating the sophisticated engineering that underpins modern mining operations.

The primary function of a coal mine control box is to act as the nerve center for a specific piece of equipment or a localized section of the mining operation. It serves as an intermediary between the power source and the heavy-duty machinery, ensuring that electrical energy is delivered in a controlled and protected manner. Without such a device, the direct connection of high-power equipment to the electrical grid would be perilous, leading to potential equipment damage, electrical faults, and catastrophic safety hazards. The control box provides a centralized point for operation and oversight, allowing for both manual intervention and automated control based on inputs from various sensors and control systems. The fundamental purpose of the control box is to provide a secure interface between human operators, automated control systems, and the powerful machinery they command. This tripartite relationship is the cornerstone of modern industrial automation and safety.

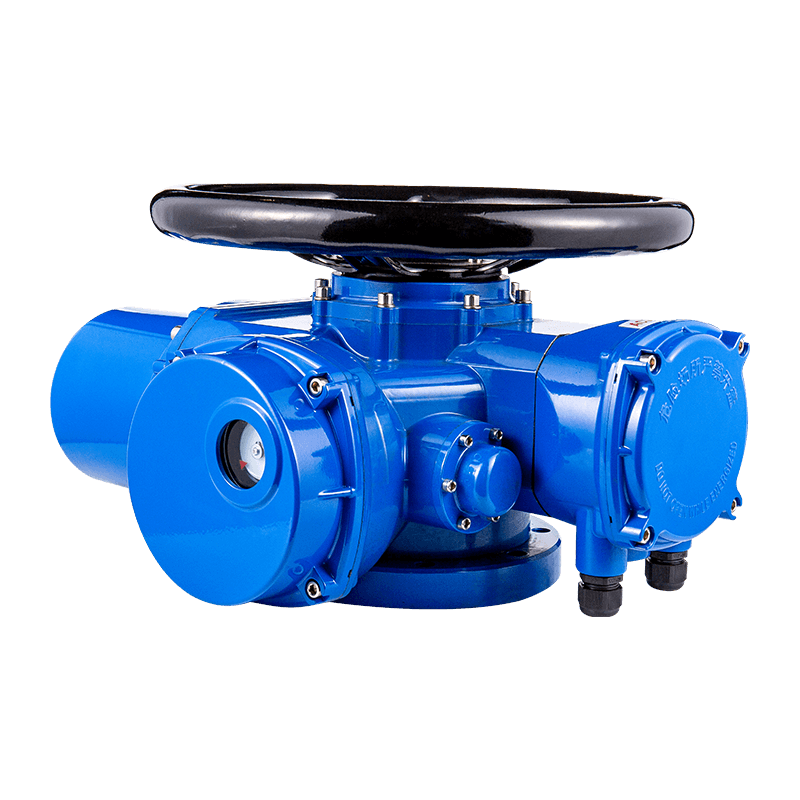

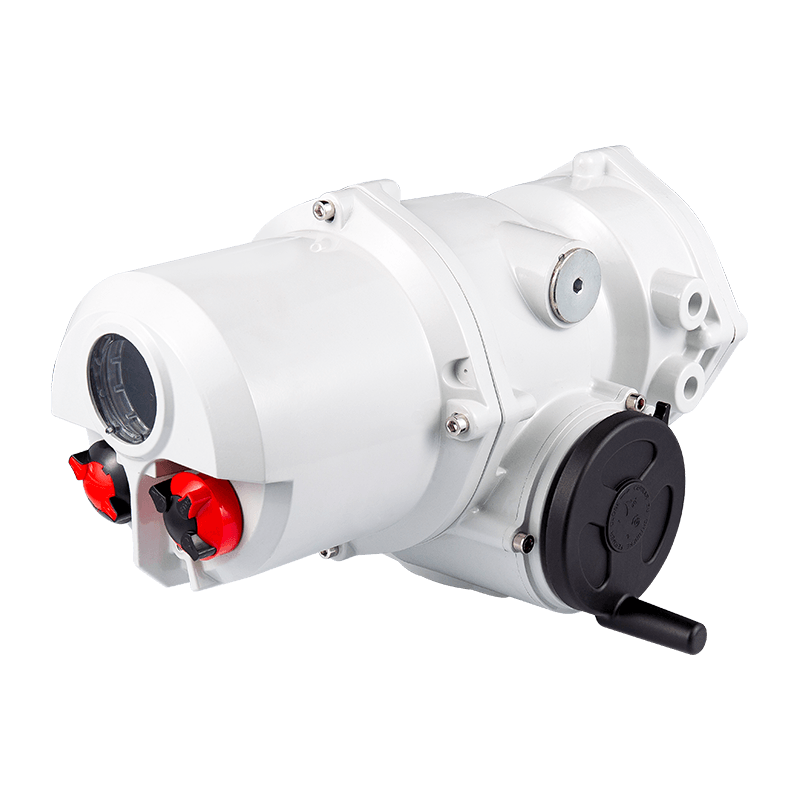

The environment within a coal mine presents a unique set of challenges that directly influence the design and construction of every piece of equipment, especially electrical components. The control box is no exception. It must be engineered to withstand conditions that would rapidly degrade standard industrial equipment. The most critical design consideration is the mitigation of explosion risks, which is addressed through the construction of explosion-proof enclosures. These enclosures are not merely robust boxes; they are meticulously engineered containers designed to withstand an internal explosion of flammable gases or dusts without allowing the flame or pressure to propagate to the external hazardous atmosphere. They are constructed from heavy-duty, durable materials like cast iron or hardened steel, with precisely machined flanges that cool any escaping gases and contain any internal pressure rise.

Furthermore, the internal atmosphere of a mine is often characterized by high levels of dust, moisture, and corrosive gases. To combat this, control boxes are sealed to very high ingress protection (IP) ratings, ensuring that harmful particulates and liquids cannot penetrate the enclosure and compromise the sensitive components within. The internal components themselves are often conformally coated, a process that applies a protective polymeric layer to circuit boards to insulate them from moisture and contamination. Robust construction and high ingress protection ratings are non-negotiable features for any device operating in the subterranean environment of a coal mine. This ruggedization ensures the longevity and reliability of the equipment, reducing the frequency of maintenance and replacement in locations where such activities are difficult and dangerous to perform.

Internally, a coal mine control box is a carefully orchestrated assembly of electrical and electronic components. While the specific configuration varies dramatically based on its intended application—whether it is controlling a massive conveyor belt drive or a local water pump—the core components share commonalities. The heart of the system often involves motor contactors or starters, which are heavy-duty relays capable of handling the high currents required by industrial motors. These are coupled with overload protection devices that monitor current flow and will disconnect the motor if it draws excessive current, a condition that could indicate a mechanical jam or motor failure, preventing burnout and potential fire.

Circuit breakers and fuses provide essential short-circuit protection, instantly isolating sections of the circuit in the event of a fault. Programmable Logic Controllers (PLCs) or specialized microprocessor-based relays are increasingly common, providing the intelligence for automated control. These devices receive input from sensors (e.g., temperature, pressure, flow, position) and execute pre-programmed logic to control the output devices accordingly. The integration of intelligent controllers like PLCs has transformed the coal mine control box from a simple switching station into a sophisticated data acquisition and processing node. This allows for predictive maintenance, complex interlocking with other systems, and detailed operational logging. Power supplies, terminal blocks for orderly wiring, and human-machine interface (HMI) components such as buttons, indicator lights, and sometimes even small display screens round out the typical internal architecture.

| Component Category | Specific Examples | Primary Function |

|---|---|---|

| Power Switching & Protection | Contactors, Motor Starters, Circuit Breakers, Fuses | To safely connect/disconnect power and protect against overloads and short circuits. |

| Control Intelligence | Programmable Logic Controllers (PLCs), Relays, Timers | To execute logic-based automated control sequences based on sensor input. |

| Operator Interface | Push Buttons, Selector Switches, Indicator Lamps, HMI Displays | To allow manual control and provide clear status feedback to operators. |

| Power Conversion | Transformers, Power Supplies | To convert incoming power to voltages required by control circuitry and sensors. |

| Interfacing | Terminal Blocks, Communication Modules (e.g., Ethernet, Profibus) | To facilitate orderly wiring and connect to broader mine monitoring networks. |

The paramount importance of the coal mine control box lies in its immense contribution to safety. It is a primary vehicle for implementing essential safety protocols. Emergency stop functions, for instance, are hardwired directly into the control circuit in a fail-safe manner. This means that pressing an emergency stop button or the triggering of a safety sensor will break the control circuit, guaranteeing a shutdown of equipment regardless of the state of the programmable controller. Intrinsic safety barriers are often incorporated into circuits connected to sensors in the most volatile areas, designed to limit the electrical energy available in the connecting wiring to a level below that which could ignite a specific hazardous atmospheric mixture.

Ventilation control is another critical safety function managed by these systems. Control boxes regulate powerful fans that ensure a constant supply of fresh air, diluting and removing dangerous gases like methane and carbon monoxide. The failure of a ventilation fan is a serious event, and the control systems are designed with redundancies and alarms to immediately alert personnel to any problem. Furthermore, control boxes for pumps play a vital role in water management, preventing inundation of working sections. By integrating monitoring and control, these systems create a layered defense against the myriad hazards present underground, making them indispensable for protecting human life and infrastructure.

Beyond safety, the drive for operational efficiency is a major factor in the evolution of control box technology. Modern units contribute significantly to energy management. Soft starters and variable frequency drives (VFDs), often housed within specialized control enclosures, allow for the gradual ramping up of motor speed. This eliminates the high inrush current associated with direct-on-line starting, reducing stress on the electrical distribution system and mechanical components like conveyor belts and gearboxes. This not only extends equipment life but also results in substantial energy savings. The ability to precisely control motor speed through variable frequency drives allows for optimized process flow and significant reductions in energy consumption.

Predictive maintenance is another efficiency gain. Intelligent controllers within the control box can continuously monitor operational parameters such as motor current, bearing temperature, and vibration levels. By analyzing trends in this data, maintenance can be scheduled based on actual equipment condition rather than on a fixed calendar basis. This prevents unexpected downtime from catastrophic failures and ensures that maintenance resources are used optimally, only intervening when necessary. This data can be communicated to a surface-based monitoring station, providing a comprehensive overview of the health and status of the mine’s vital equipment.

The installation, calibration, and ongoing maintenance of a coal mine control box are procedures governed by strict protocols. Only qualified and certified personnel are permitted to work on this equipment. During installation, every connection must be meticulously checked for tightness, and the integrity of the explosion-proof flanges and seals must be verified. Calibration of sensors and setpoints for protection devices must be performed precisely according to the machine’s specifications and the mine’s operating parameters. Routine maintenance is not optional; it is a critical safety and operational requirement. This involves periodic inspections to check for signs of corrosion, damage to cables and conduits, and the tightness of electrical connections, which can loosen over time due to vibration. The internal atmosphere of the box must be kept clean and dry, often maintained by using internal air conditioning units or heaters designed for hazardous areas.

Finally, the field of mining technology is not static, and the coal mine control box continues to evolve. The trend is toward greater integration and smarter, more connected systems. Future iterations will feature even more sophisticated embedded sensors and wireless communication capabilities, enabling a higher degree of condition monitoring and integration with mine-wide digital ecosystems, often referred to as mine digitization. The future of mine control lies in the deeper integration of IoT principles, creating a network of intelligent devices that communicate seamlessly to optimize the entire mining operation. This could lead to more autonomous operations, where systems can self-diagnose faults, automatically reconfigure to maintain production after a localized failure, and provide rich, real-time data for operational decision-making. However, this increased connectivity also brings new challenges, particularly in the realm of cybersecurity for critical industrial infrastructure, which will become an increasingly important design consideration.

In conclusion, the coal mine control box is a masterpiece of specialized engineering. It is far more than a simple junction box; it is a critical system that ensures the safe, reliable, and efficient operation of mining machinery in an profoundly hostile environment. Its design is a direct response to the extreme hazards of methane, coal dust, and moisture, resulting in a rugged, sealed, and intelligent assembly of components. From its primary role in enforcing vital safety protocols to its growing contribution to energy efficiency and predictive maintenance, the control box is an indispensable asset. As mining technology advances, this humble yet complex box will continue to be the fundamental building block upon which safer, more productive, and more sustainable mining operations are built. Its uninterrupted and reliable function is a silent guardian of both the mine’s operational integrity and, most importantly, the lives of those who work within it.

русский

русский Español

Español