0086 15335008985

Multi-turn electric actuator: principle, application

In the field of modern industrial automation, multi-turn electric actuators, as a key driving device, play an indispensable role. They can efficiently convert electrical energy into mechanical rotation, accurately control the operation of various equipment, and are widely used in many industries such as energy, chemical industry, and water conservancy. With the continuous advancement of technology, multi-turn electric actuators have achieved significant improvements in performance, function, and intelligence, providing a strong guarantee for the efficient, accurate, and safe operation of industrial production.

What is a multi-turn electric actuator ?

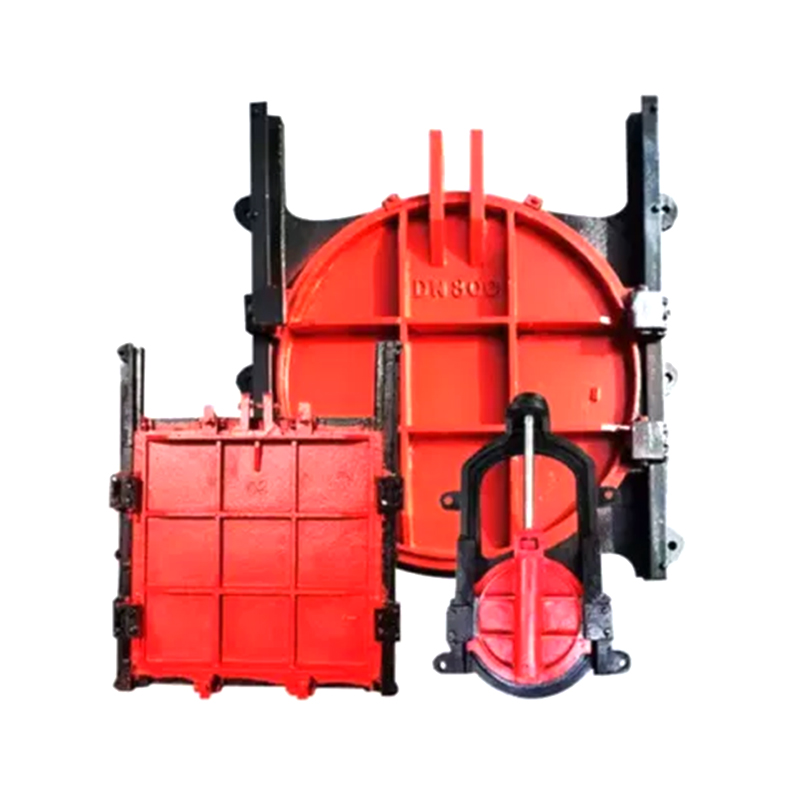

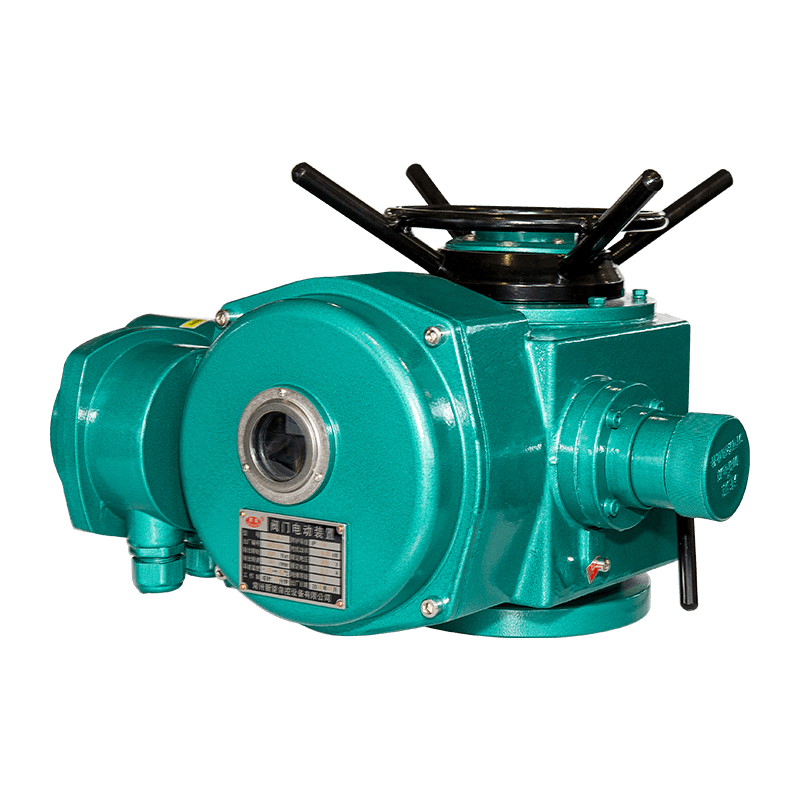

A multi-turn electric actuator is an automatic control device that can convert electrical energy into multi-turn rotational motion output. It is mainly used to drive equipment that requires multiple turns of rotation to achieve full opening, full closing or precise adjustment. The most common application objects are various valves, such as gate valves, stop valves, plunger valves, etc. Unlike partial-turn electric actuators that can only achieve 90 degrees or less than 360 degrees of rotation, multi-turn electric actuators can achieve continuous rotation of multiple turns (usually more than 1 turn), thereby meeting the needs of some equipment for large stroke and high-precision control.

Working principle of multi-turn electric actuator

The working principle of multi-turn electric actuator is based on the coordinated operation of motor drive and mechanical transmission. Take the common multi-turn electric actuator based on three-phase asynchronous motor as an example:

l Power input : When the power is turned on, the three-phase asynchronous motor starts to run and outputs high-speed rotating mechanical energy. The rotation speed of the motor is usually high, generally between several hundred and several thousand revolutions per minute, but its output torque is relatively small.

l Reduction drive : Since the opening and closing of equipment such as valves requires a large torque and a low speed, a reduction mechanism is needed to match the output characteristics of the motor. The reduction mechanism is generally composed of worm gears, gear sets and other components. The high-speed rotation of the motor is transmitted by the worm gear or gear set, and the speed is gradually reduced, while the torque is increased according to the transmission ratio. For example, through the worm gear transmission, the high-speed and low-torque output of the motor can be converted into a low-speed and high-torque output of the output shaft, so that the output shaft can drive the valve at a suitable speed and torque.

l Operation of the control section : The control section is the core of the multi-turn electric actuator. It receives control signals from the control system, such as 4-20mA current signals, 0-10V voltage signals or digital communication signals. These signals represent the command requirements for the output position or action of the actuator. The control section compares the received control signal with the actual position signal fed back by the internal position feedback device of the actuator, and generates control instructions based on the comparison results to control the forward, reverse or stop of the motor. For example, when the control signal requires the valve opening to increase, if the actual valve opening is less than the set value, the control section will control the motor to rotate forward, driving the valve to rotate in the direction of increasing the opening; when the actual valve opening reaches the set value, the control section will control the motor to stop running.

l Position feedback : In order to let the control system know the running status of the equipment in real time, the multi-turn electric actuator is equipped with a position feedback device. Common position feedback devices include potentiometers, encoders, etc. When the output shaft of the actuator drives the equipment (such as a valve) to rotate, the components of the position feedback device will also rotate synchronously, converting the actual position of the equipment into an electrical signal or digital signal to feed back to the control part or remote control system. Through position feedback, the control system can accurately grasp the opening of the equipment and realize precise control and monitoring of the equipment.

Classification of multi-turn electric actuators

1. Classification by drive motor type

l AC motor drive type : the most widely used, common ones are three-phase AC asynchronous motors and single-phase AC motors. Three-phase AC asynchronous motors have the advantages of simple structure, reliable operation, low cost, and high output power. They are suitable for occasions with high output torque requirements and large loads, such as the drive of large industrial valves. Single-phase AC motors are often used in some small multi-turn electric actuators, suitable for application scenarios with low power and low power requirements, such as small valve control in civil buildings.

l DC motor driven type : DC motors have good speed regulation performance and can achieve relatively accurate speed control. In some occasions where the actuator speed regulation accuracy is high and frequent start and stop or forward and reverse rotation is required, multi-turn electric actuators driven by DC motors have advantages. For example, in some experimental equipment or small industrial systems with extremely high flow control accuracy requirements, multi-turn electric actuators driven by DC motors may be used. Its disadvantages are that it needs to be equipped with a DC power supply, the cost is relatively high, and the maintenance requirements of the motor are relatively high.

l Stepper motor driven type : Stepper motors can convert electrical pulse signals into angular displacement. Each time a pulse signal is received, the motor rotates a fixed angle, namely the step angle. This characteristic enables multi-turn electric actuators driven by stepper motors to have high positioning accuracy and achieve precise position control. Multi-turn electric actuators driven by stepper motors are used in some occasions that require extremely high positioning accuracy of valve opening, such as semiconductor manufacturing, precision chemical industry and other industries. However, their output torque is relatively small and their operating speed is also subject to certain restrictions.

l Servo motor driven type : Servo motors have the advantages of fast response speed, high control accuracy, and strong overload capacity. Multi-turn electric actuators driven by servo motors can respond to control signals quickly and accurately, and achieve high-speed and high-precision control of valves and other equipment. In some occasions where the dynamic performance of the actuator is extremely high, such as the control of high-speed switch valves and the rapid action execution in automated production lines, multi-turn electric actuators driven by servo motors perform well. However, their cost is relatively high and the control system is relatively complex.

2. Classification by control method

l Open-loop control type : After receiving the control signal, the multi-turn electric actuator with open-loop control drives the motor to operate according to the preset program to complete the corresponding action, such as opening or closing the valve. It does not have the function of feedback detection and correction of the actual execution result. The control accuracy mainly depends on the accuracy of the motor and transmission mechanism and the preset control parameters. This control method has a simple structure and low cost. It is suitable for some occasions with low control accuracy requirements, relatively stable working environment, and small load changes, such as valve control in some simple ventilation systems.

l Closed-loop control type : The closed-loop controlled multi-turn electric actuator detects the output position of the actuator in real time through the position feedback device, and feeds back the position signal to the controller. The controller compares the feedback signal with the input control signal, and adjusts the operation of the motor according to the comparison result to ensure that the output position of the actuator is consistent with the position required by the control signal. This control method can effectively improve the control accuracy, adapt to various complex working environments and load changes, and is widely used in industrial automation fields with high control accuracy requirements, such as flow control valve control in chemical production, valve control in power systems, etc.

Features of multi-turn electric actuators

l High-precision control : Through advanced control algorithms and precise position feedback devices, multi-turn electric actuators can achieve high-precision control of valve opening or equipment position, with a control accuracy of ±0.1% or even higher. This enables precise adjustment of medium flow, pressure and other parameters during industrial production, ensuring the stability of the production process and consistency of product quality.

l Large torque output : The reduction mechanism equipped with the multi-turn electric actuator can convert the high-speed and low-torque output of the motor into the low-speed and high-torque output of the output shaft. The output torque range can be from tens of Newton meters to tens of thousands of Newton meters, which can meet the driving requirements of valves and other equipment of different specifications and types, and is especially suitable for driving large and heavy valves.

l Fast response speed : After receiving the control signal, the multi-turn electric actuator can respond quickly, drive the motor to start, stop or change direction quickly, and realize the rapid action of the equipment. For some valves that need to be opened and closed quickly, such as emergency shut-off valves, the multi-turn electric actuator can complete the opening or closing of the valve in a short time to ensure the safety of the production process.

l High reliability : Multi-turn electric actuators use mature motor technology and reliable mechanical transmission components. After strict quality inspection and durability testing, they have high reliability and stability. Under normal working conditions, their mean time between failures (MTBF) can reach thousands or even tens of thousands of hours, reducing equipment maintenance and downtime and improving production efficiency.

l High degree of intelligence : Modern multi-turn electric actuators are usually equipped with intelligent controllers, which have functions such as data communication, fault diagnosis, self-protection, and remote control. Through communication interfaces (such as RS485, Modbus, Profibus, etc.), data can be exchanged with the upper control system to achieve remote monitoring and operation. At the same time, the intelligent controller can monitor the operating status of the actuator in real time, analyze parameters such as motor current, temperature, position, etc., detect and diagnose faults in time, and take corresponding protection measures, such as overcurrent protection, overheating protection, overload protection, etc., to improve the safety and reliability of the equipment.

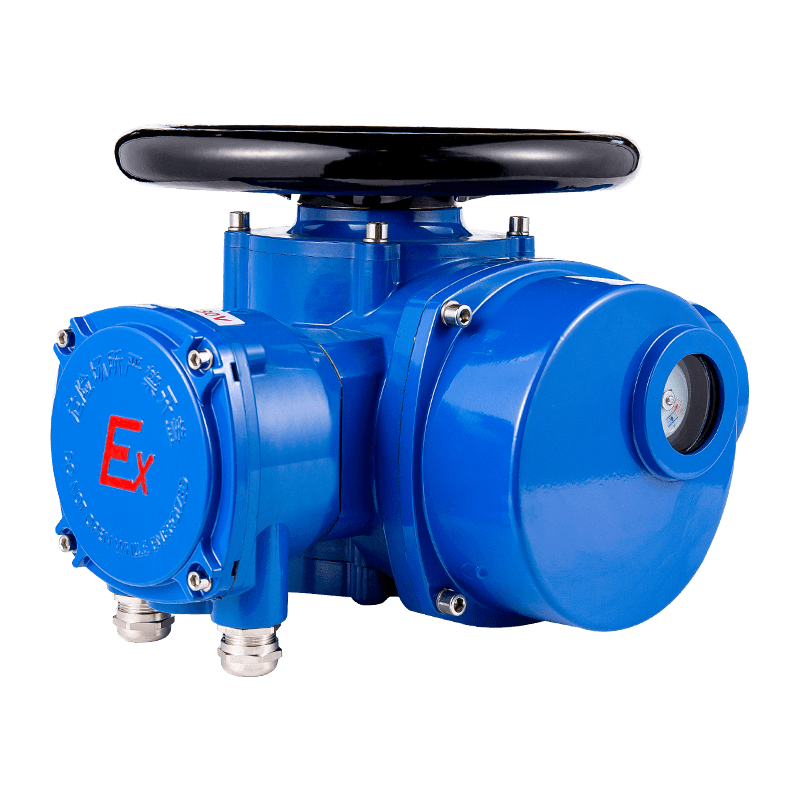

l Strong adaptability : Multi-turn electric actuators can be customized according to different working environments and application requirements, such as explosion-proof, waterproof, dust-proof, etc. Explosion-proof multi-turn electric actuators can operate safely in flammable and explosive dangerous environments and are widely used in industries such as petroleum, chemical, and natural gas; waterproof and dust-proof multi-turn electric actuators are suitable for humid, dusty and other harsh environments, such as sewage treatment plants, mines and other places.

Application areas of multi-turn electric actuators

1. Energy Industry

l Oil and gas : In the process of oil and gas extraction, transportation and processing, multi-turn electric actuators are widely used to control various valves. For example, in wellhead devices, they are used to control the opening and closing of Christmas tree valves to achieve precise regulation of oil and gas extraction; on oil and gas pipelines, they control gate valves, stop valves, etc. to ensure the safe operation and flow regulation of pipelines; in refineries and natural gas processing plants, they are used to control various process valves to achieve automated control of oil and gas separation, purification and other process processes.

l Electricity : Multi-turn electric actuators play an important role in power production fields such as thermal power generation, hydropower generation, and nuclear power generation. In thermal power plants, they are used to control the boiler's feedwater valve, steam valve, burner damper, etc., to achieve precise control of the boiler combustion process, steam flow and water level, and ensure the stable operation of the generator set; in hydropower plants, they are used to control the guide vane opening and water inlet valve of the turbine, adjust the output of the turbine, and achieve control of the power generation; in nuclear power plants, they are used to control the coolant valve and safety valve of the nuclear reactor, and ensure the safe and stable operation of the nuclear power plant.

2. Chemical Industry

The chemical production process involves many complex chemical reactions and material transportation, which requires extremely high control accuracy and reliability of valves. Multi-turn electric actuators are widely used in various links of chemical production, such as raw material transportation, reaction process control, product separation and purification, etc. For example, in a chemical reactor, the opening of the feed valve and the discharge valve is controlled to accurately adjust the flow rate and reaction time of the reaction materials to ensure the smooth progress of the chemical reaction; in a distillation tower, the reflux valve and the discharge valve are controlled to achieve precise control of the distillation process and improve the purity and quality of the product.

3. Water conservancy industry

In water conservancy projects, multi-turn electric actuators are used to control various hydraulic valves, such as flood discharge gate valves of dams, water diversion valves in irrigation systems, sluice gates and stop valves in urban water supply systems, etc. Through precise control of these valves, reasonable allocation of water resources, flood control and drought relief, and safety of urban water supply can be achieved. For example, before a flood comes, the flood discharge gate valve can be quickly opened by remotely controlling the multi-turn electric actuator to timely drain the flood and ensure the safety of the dam and downstream areas; in the irrigation season, the opening of the water diversion valve can be accurately adjusted according to the water demand of the farmland to achieve efficient use of water resources.

4. Metallurgical Industry

In the process of metallurgical production, it is necessary to control high-temperature, high-pressure, and highly corrosive media. Multi-turn electric actuators are suitable for various harsh environments in the metallurgical industry and are used to control the hot air valves, gas valves, oxygen lance lifting valves of steelmaking converters, etc. Through the precise control of these valves, stable control of parameters such as temperature, pressure, and flow in the metallurgical production process can be achieved, improving production efficiency and product quality while ensuring the safety of the production process.

5. Construction and Municipal Engineering

In the field of construction and municipal engineering, multi-turn electric actuators are used to control valves in the heating, ventilation and air conditioning (HVAC) system in buildings, such as hot water regulating valves, fresh air valves, etc., to achieve automatic adjustment of indoor temperature, humidity and air quality, and improve the comfort and energy efficiency of buildings. In municipal water supply and sewage treatment systems, multi-turn electric actuators are used to control sluice gates, check valves, regulating valves, etc. to ensure the safety of urban water supply and the normal operation of sewage treatment.

Production Technology of Multi-turn Electric Actuators

1. Parts processing

l Motor manufacturing : Choose the appropriate motor design according to different motor types (such as AC motors, DC motors, stepper motors, servo motors). For AC motors, it is necessary to carry out processes such as stator core punching, winding and inserting, and rotor manufacturing; for DC motors, it is also necessary to manufacture the commutator and install the brush device. During the motor manufacturing process, there are strict requirements for the material selection of the core, punching accuracy, and insulation treatment of the winding to ensure the performance and reliability of the motor.

l Processing of reduction mechanism : The main parts of the reduction mechanism, such as worm gears, worm shafts, gears, etc., are usually processed with high-quality metal materials (such as alloy steel, copper alloy, etc.). Worm gears and worm shafts are generally manufactured through turning, milling, grinding and other processes to ensure their tooth profile accuracy and surface roughness; gears are processed through hobbing, shaping, shaving and other processes, and heat treatment (such as quenching, tempering, etc.) is required to improve the hardness and wear resistance of the gears.

l Manufacturing of housing and other parts : The housing of multi-turn electric actuators is generally manufactured by casting or sheet metal processing. The casting process can use sand casting, die casting and other methods to produce housings with complex shapes; sheet metal processing uses shearing, bending, welding and other processes to produce compact housings. In addition, it is also necessary to process and manufacture various standard parts such as shafts, keys, nuts, and non-standard parts such as mounting brackets for position feedback devices (such as potentiometers and encoders).

2. Assembly and commissioning

l Component assembly : First, assemble the processed motor and the reduction mechanism to ensure that the motor output shaft and the input shaft of the reduction mechanism are connected accurately and the concentricity meets the requirements. Then install the position feedback device and connect it to the output shaft or transmission component of the actuator to ensure the accuracy of the position feedback. Then install electrical components such as the control circuit board, terminal blocks, display panel, and manual operation components such as handwheels and clutches. During the assembly process, it is necessary to strictly follow the assembly process requirements, control the matching clearance between the components, use appropriate tightening tools and torque to ensure assembly quality.

l Machine debugging : After assembly, the multi-turn electric actuator is fully debugged. First, the electrical performance test is carried out to check whether the insulation resistance, starting current, running current and other parameters of the motor meet the standards; then the control performance test is carried out to check whether the actuator's response speed, positioning accuracy, direction of action, etc. are correct by inputting different control signals; at the same time, the feedback signal of the position feedback device is tested to be accurate and consistent with the actual position. During the debugging process, the problems found are adjusted and repaired in a timely manner to ensure that the performance indicators of the actuator meet the design requirements.

3. Quality testing and certification

l Quality inspection : Multi-turn electric actuators need to undergo strict quality inspection before leaving the factory, including appearance inspection, dimensional measurement, performance testing, etc. Appearance inspection mainly checks whether the shell has scratches, deformation, coating shedding and other defects; Dimensional measurement ensures that the dimensions of each component meet the requirements of the design drawings; Performance testing, in addition to the above-mentioned electrical performance and control performance tests, also includes testing of the actuator's torque output, protection level (such as waterproof, dustproof, explosion-proof performance), durability, etc. By simulating the actual working environment and working conditions, the actuator is tested for a long time to check its reliability and stability under various conditions.

l Certification : In order to meet the needs of different industries and markets, multi-turn electric actuators need to obtain relevant certifications, such as CE certification (in compliance with European safety, health and environmental standards), UL certification (Underwriters Laboratories certification), explosion-proof certification (such as Ex certification, suitable for flammable and explosive environments), etc. Through the certification process, it is ensured that the actuator complies with relevant international or domestic standards and specifications, and the market competitiveness and recognition of the product are improved.

русский

русский Español

Español