0086 15335008985

Cat:Quarter Turn Electric Actuator

The QM series partial rotary valve electric device includes ordinary switch type, integral type, regulating type, intell...

See Details

Efficient conversion mechanism of compressed air energy

As a key device for fluid control in the field of industrial automation, the core function of rack and pinion pneumatic actuator is to accurately convert the pressure energy of compressed air into mechanical energy, thereby driving various valves to complete switching or adjustment operations. This energy conversion process relies on the precise meshing structure of gears and racks. When compressed air enters the cylinder, it pushes the piston to produce linear motion, which in turn drives the rack connected to it to move. The linear displacement of the rack is converted into the rotational motion of the gear through the meshing relationship, and finally the opening and closing of the valve is realized.

Adaptability to the industrial field under safety orientation

The wide application of rack and pinion pneumatic actuator is largely due to its inherent safety and explosion-proof characteristics, which makes it occupy an irreplaceable position in industrial scenarios with strict requirements on production safety. In the thermal system of a power plant, due to the high temperature and high pressure environment and the possible presence of flammable media, the explosion-proof performance of the actuator is directly related to the safety of the system operation. Its pneumatic drive method without electric sparks effectively avoids potential risks; in the chemical and oil refining industries, the presence of various corrosive media and flammable and explosive gases requires the control equipment to have stable anti-interference capabilities. The rack and pinion pneumatic actuator eliminates the safety hazards caused by electrical failures through the design of non-electric drive.

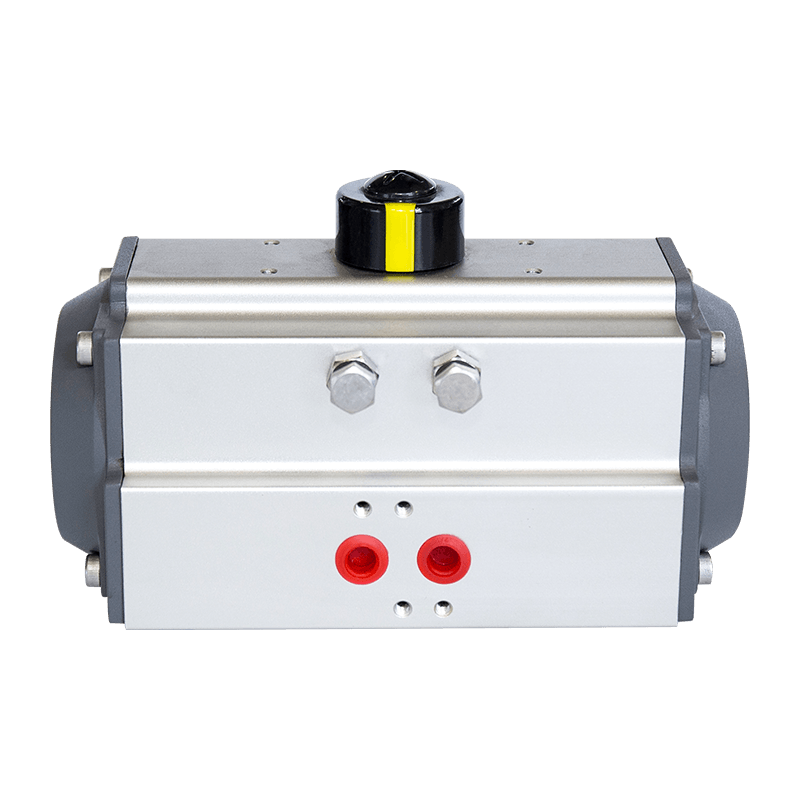

Compact structure and multi-functional adaptation

The rack and pinion pneumatic actuator is significantly compact in design, which enables it to flexibly adapt to a variety of valve types such as butterfly valves, plug valves and ball valves, especially suitable for industrial environments with limited installation space. Its structural design fully considers the diverse needs of industrial control and generally has two core functions: double-acting and spring reset. In the double-acting mode, the switching action of the actuator is driven by compressed air, and it can achieve precise stop at any position to meet the needs of complex adjustment scenarios; the spring reset function uses the elastic force of the pre-compressed spring to automatically return the valve to the preset safe position when the air source is interrupted, providing a reliable fault protection mechanism for the system. In terms of performance, for rack and pinion actuators with a 100-degree stroke, limit blocks are set at both ends of the stroke to ensure the position accuracy of the valve in the fully open or fully closed state through mechanical limit, avoiding equipment damage due to excessive movement. The actuator is equipped with an ISO standard mounting platform driven by a star gear. This platform provides a unified mounting interface for valve accessories, is compatible with various standard valve accessories, and enhances the scalability of the equipment; the integration of auxiliary equipment brackets facilitates the installation of auxiliary devices such as position sensors and limit switches, further improving the integration of the actuator in the automation control system.

Corrosion-resistant solutions for various working conditions

The material selection of rack and pinion pneumatic actuators directly determines their adaptability to different working environments. As the core pressure-bearing component, the cylinder is usually made of two mainstream materials: aluminum alloy or stainless steel. Aluminum alloy material, with its lightweight characteristics, effectively reduces the overall weight of the actuator, making it easy to install and maintain. Through surface anodizing and other treatment processes, it can significantly improve its resistance to atmospheric corrosion, and is suitable for dry industrial environments without strong corrosive media; stainless steel material is known for its excellent acid and alkali resistance. In scenes where corrosive gases or liquids exist, such as chemical and marine engineering, it can maintain structural stability for a long time and avoid seal failure or action jamming due to material corrosion. In addition to cylinder materials, transmission parts such as gears and racks are mostly made of high-strength alloy steel, and are precision machined and surface hardened to ensure sufficient wear resistance and fatigue resistance in long-term meshing movement. Seals are made of materials such as nitrile rubber and fluororubber according to the characteristics of the working medium, taking into account both sealing performance and service life, so that the actuator can maintain reliable operation under complex working conditions such as high and low temperatures and humidity. This diversified material combination strategy enables rack and pinion pneumatic actuators to easily cope with various scene requirements from conventional industrial environments to extreme corrosive conditions.