What are the key factors to consider when selecting a globe valve in high temperature or high pressure applications?

When selecting a globe valve in high temperature or high pressure applications, the following key factors need to be considered to ensure that the valve can operate reliably under extreme conditions:

1. Material selection

High temperature applications: In high temperature environments, the material of the valve must be able to withstand thermal expansion, corrosion and oxidation. Commonly used high temperature resistant materials include stainless steel (such as 304, 316), alloy steel (such as Inconel, Hastelloy) and ceramics. The heat resistance and corrosion resistance of the material directly affect the service life of the valve.

High pressure applications: In high pressure environments, the material of the valve must have high compressive strength and fatigue resistance. Commonly used materials include high alloy steel, carbon steel and special alloy materials that can withstand pressure shocks and maintain structural integrity.

2. Sealing performance

Under high temperature or high pressure conditions, the sealing performance of the globe valve is particularly important. It is necessary to select valve seat and valve core materials with good sealing performance, such as flexible graphite, polytetrafluoroethylene (PTFE) seals, or high temperature special sealing materials.

The sealing surface should be wear-resistant and corrosion-resistant to ensure that the valve can effectively prevent leakage even after long-term use.

3. Valve design

Valve body structure: Under high temperature and high pressure conditions, the valve body design needs to be able to withstand greater internal pressure and temperature changes. Generally speaking, choosing a double-acting valve body structure (such as a fully welded valve body) is more suitable for high-pressure applications because it has a strong pressure resistance.

Valve flap design: For high pressure and high temperature environments, the valve flap needs to be designed to be resistant to high temperature and wear, and can move flexibly under extreme pressure. The streamlined design of the valve flap helps to reduce flow resistance and wear during fluid flow.

4. Operating temperature and pressure range

When selecting a stop valve, it is necessary to confirm whether the maximum operating pressure and operating temperature of the valve meet the application requirements. The valve usually indicates its safe operating range under high temperature or high pressure, and exceeding this range may cause the valve to fail.

At high temperatures, the valve may undergo thermal expansion, so when selecting, consider the impact of temperature changes on valve size and sealing performance.

5. Valve stem and drive mode

Valve stem design: In high temperature and high pressure environments, the valve stem needs to have sufficient high temperature and corrosion resistance. Materials such as stainless steel, titanium alloy or alloy steel can provide good high temperature resistance.

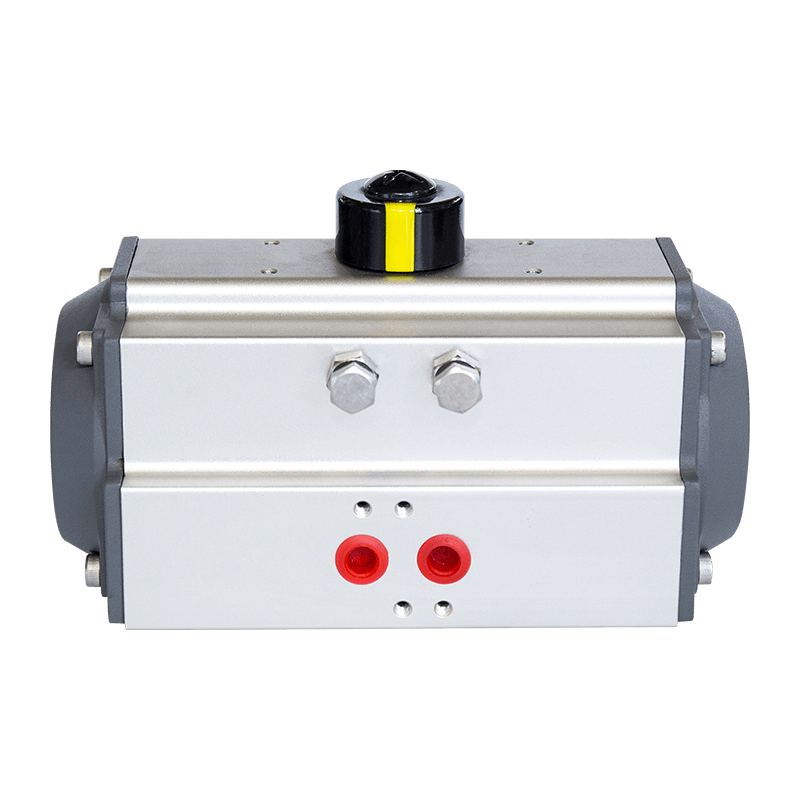

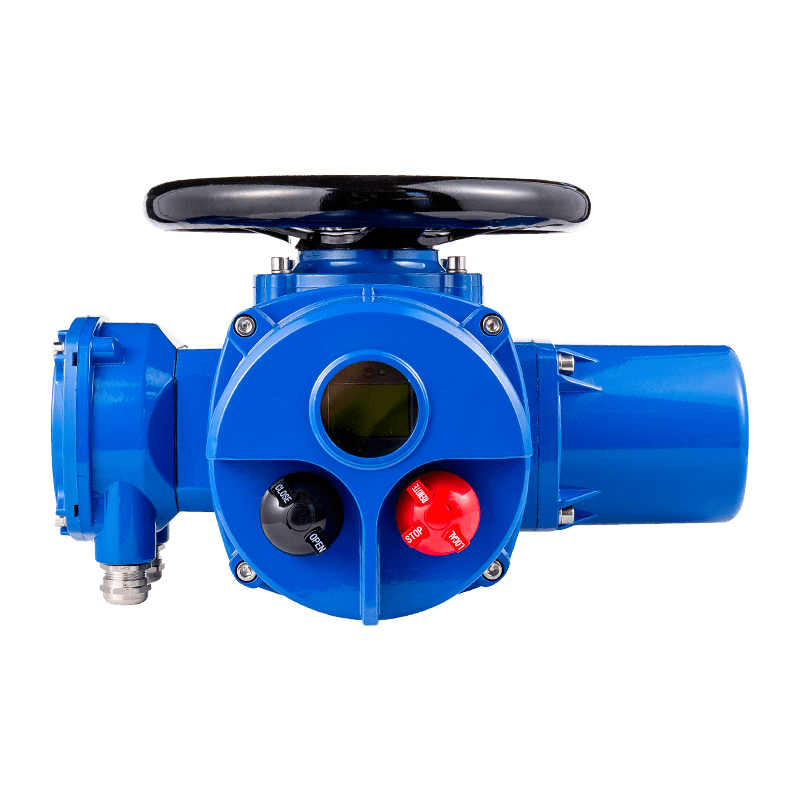

Drive mode: In high temperature or high pressure environments, it is also crucial to choose the appropriate drive mode (such as manual, pneumatic, electric or hydraulic drive). The drive system should have high temperature and pressure resistance to ensure stable operation under extreme conditions.

6. Valve size and flow control

Flow regulation accuracy: In high temperature and high pressure applications, accurate flow regulation is particularly important. Due to the thermal expansion and pressure fluctuations of the fluid, it is very important to choose the appropriate stop valve size and flow regulation range.

Fluid properties: If the fluid is corrosive or has particles, it is necessary to choose corrosion-resistant and wear-resistant materials, and consider the impact of the valve on the fluid flow under long-term high temperature and high pressure.

7. Leakage rate requirements

In high temperature or high pressure applications, any small leakage may have serious consequences (such as explosion, fire, etc.). Therefore, when selecting a stop valve, it is necessary to ensure that it has an extremely low leakage rate and high sealing.

8. Reliability and safety

High temperature and high pressure applications require very high reliability of valves. You should choose a valve design with good durability and fatigue resistance, and consider using a valve with an emergency shutdown function to avoid extreme situations.

9. Convenience of maintenance and repair

Under high temperature and high pressure conditions, the maintenance of the valve may be limited by the working conditions. Therefore, the convenience of valve maintenance should be considered when selecting, and models with simple structures and long maintenance cycles should be selected as much as possible. In addition, pay attention to the long-term stability of the valve to reduce the frequency of downtime and repairs.

русский

русский Español

Español