How to perform regular maintenance and inspection on industrial gate valves to ensure long-term reliable operation?

It is very important to perform regular maintenance and inspection on industrial gate valves to ensure long-term reliable operation and reduce sudden failures. Here are some key maintenance and inspection steps:

1. Regularly inspect the outside of the valve body

Check for leaks: Regularly check the valve body and connection parts for leaks, especially the sealing surface and valve stem of the valve. Any leakage may lead to reduced system efficiency or safety hazards.

Check for corrosion or wear: The outside of the valve body should be inspected for corrosion, cracks or other signs of wear. Corrosion will affect the structural strength of the valve, while wear may cause seal failure.

2. Clean the valve

Remove dirt and sediment: The inside and outside of the valve should be cleaned regularly, especially the sealing surface and valve stem. Sediment, dust or other dirt will affect the operating flexibility of the valve and may even cause the valve to stick.

Clean the valve channel: Keeping the valve channel unobstructed is the key to ensuring smooth fluid flow. Regularly remove any impurities that may block the flow channel.

3. Check the valve stem and drive device

Lubricate the valve stem: The valve stem should be lubricated regularly to reduce friction and prevent rust or sticking. When lubricating, make sure to use the appropriate lubricant and follow the manufacturer's recommendations.

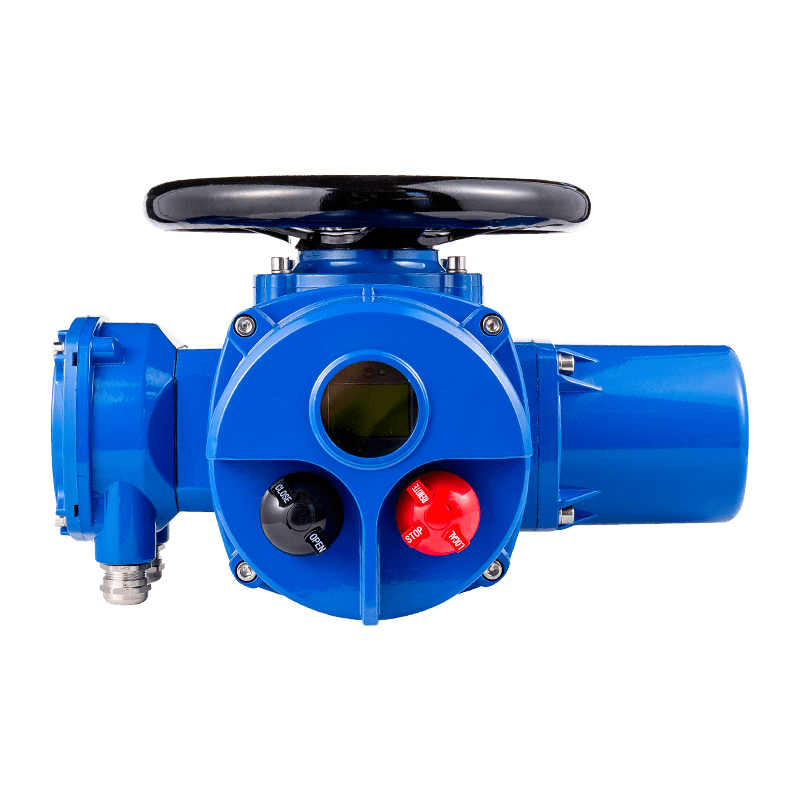

Check manual or automatic drive: For gate valves equipped with electric, pneumatic or hydraulic drives, it is necessary to regularly check the working condition of the drive, pressure settings and control signals. For manual valves, check whether the valve stem and handwheel operate smoothly.

4. Check the sealing surface and valve seat

Check the valve sealing surface: Regularly check the valve sealing surface and valve seat, especially in high temperature or high pressure working environment, the sealing surface may fail due to wear or corrosion. Worn sealing surfaces should be repaired or replaced in time.

Check the valve seat: If the valve is frequently opened and closed, the valve seat may be worn or fouled, resulting in a poor seal. Regularly check and clean the valve seat, grind or replace it if necessary.

5. Regular functional testing

Operational performance test: Regularly perform functional tests on the valve to ensure that it can open and close smoothly, seal well, and respond normally to operation in the pipeline system. Manual or automatic tests can be used to confirm the performance of the valve under different working conditions.

Test the valve response time: For automatically controlled gate valves, check whether its response time meets the requirements. Slow response may indicate a problem with the valve drive.

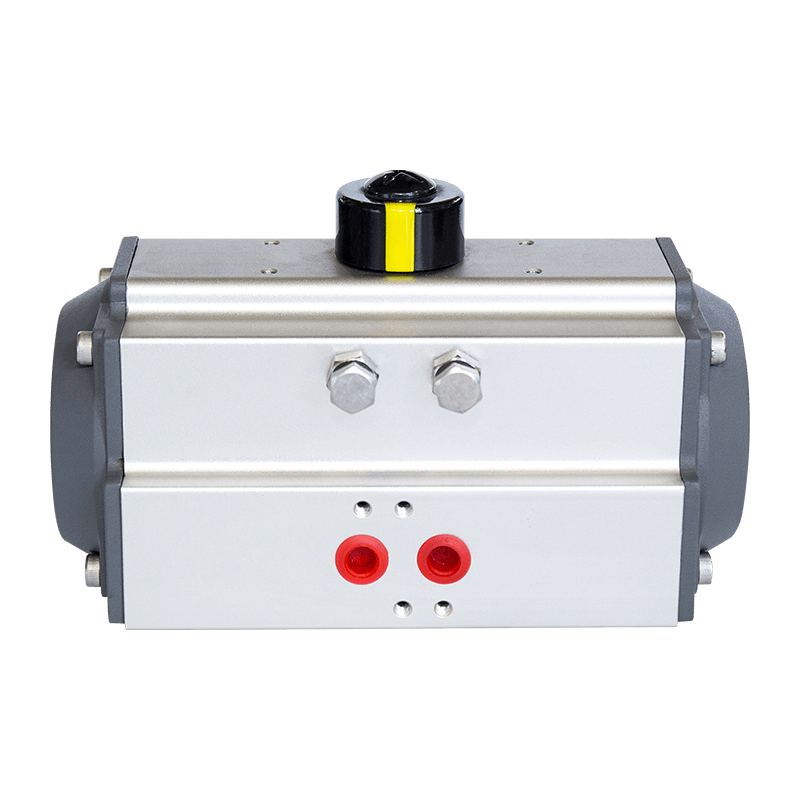

6. Check the valve positioning and actuator

Actuator inspection: For automated valves, check the positioning accuracy and the working condition of the actuator. It may be necessary to check the components of the pneumatic, hydraulic or electric actuator to ensure that there is no leakage and abnormal wear.

Valve positioner calibration: If the valve is equipped with a positioner, calibrate the positioner regularly to ensure that the valve is positioned accurately.

7. Replace consumable parts

Valve seats, seals and valve stems: Regularly check and replace consumable parts such as valve seats, seals and valve stems. In particular, these parts are more susceptible to damage under high-frequency opening and closing or extreme working conditions.

8. Regular records and reports

Maintenance records: Record the details of each maintenance, inspection and repair to track the service life and failure history of the valve. These records help identify potential problems in advance and take preventive measures.

Develop a preventive maintenance plan: According to the working environment and usage of the equipment, develop a regular preventive maintenance plan to avoid sudden failures due to neglecting details.

9. Replace damaged parts

Replace damaged parts in time: If valve parts (such as valve stems, seals, valve seats, etc.) are found to be damaged or severely worn, they should be replaced in time instead of continuing to use them. Ignoring damaged parts for a long time may lead to more serious failures or safety issues.

10. Ensure appropriate operating conditions

Operating condition monitoring: Check whether the operating conditions such as temperature, pressure, flow rate, etc. of the fluid in the system are within the design parameter range of the valve. Operating conditions beyond the design range may accelerate the wear of the valve.

русский

русский Español

Español