Changzhou Xinneng Automatic Control Equipment Co., Ltd is a technology-based enterprise specializing in research, development, production, sales, and service of various electric actuators, valves, and automatic control systems. As a

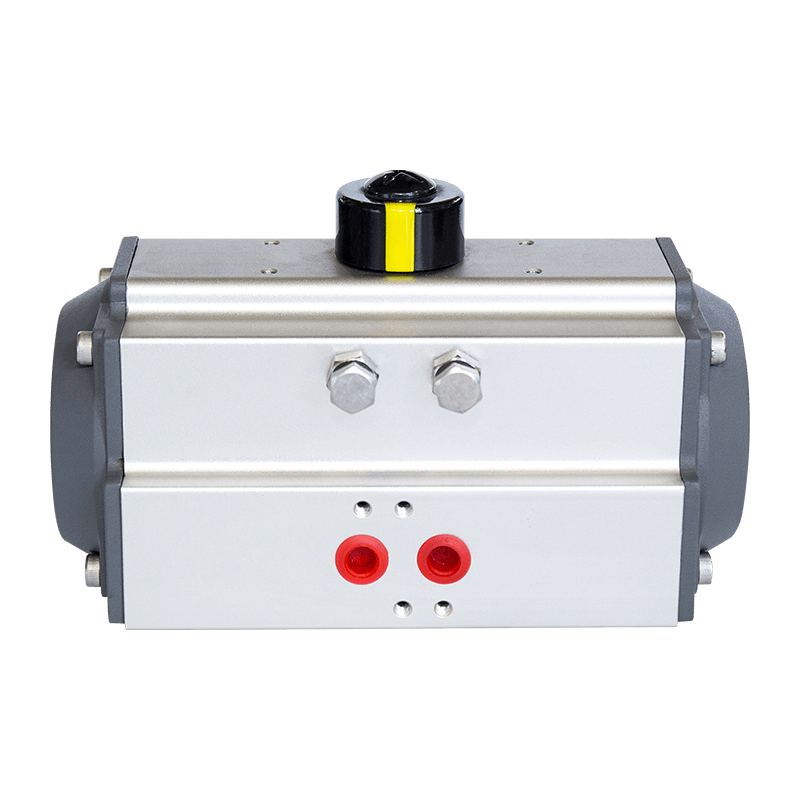

China Custom Rack and Pinion Pneumatic Actuator Suppliers and

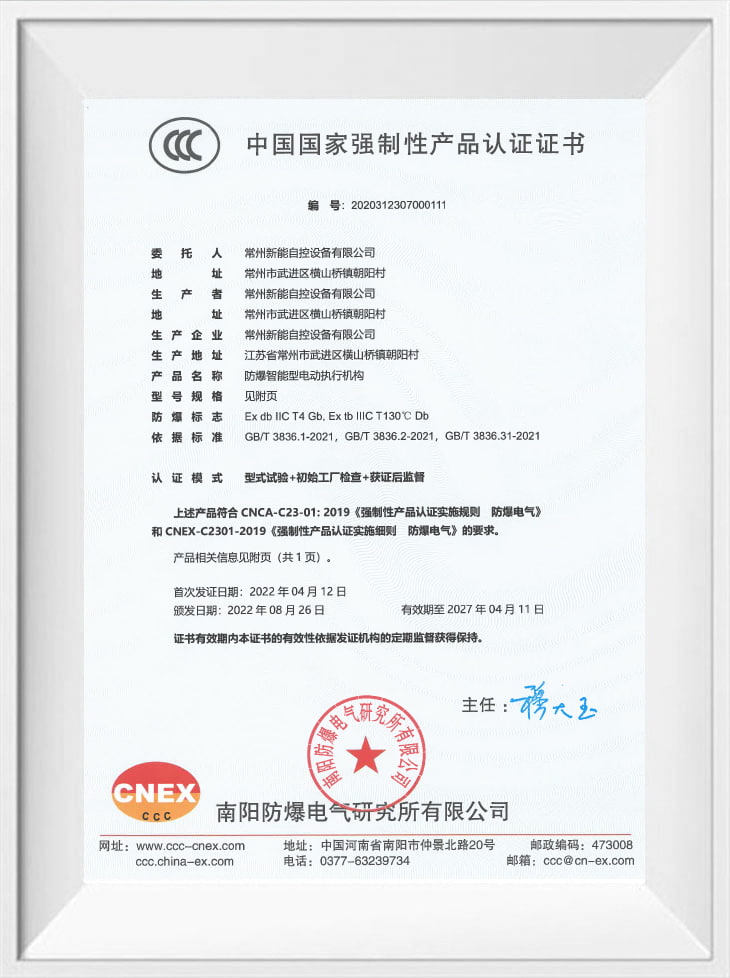

Rack and Pinion Pneumatic Actuator Manufacturers, annual production and sales of electric valve actuators of more than 10,000 sets. In 2006 through the IS09001 quality management system certification, and obtained the national "productflame-proof certification", "explosion-proof the national industrial product production permit" issued by the National Center for AnBiao "mining productssafety sign certificate", and in cooperation with the district technology bureau established the engineering research center for intelligent digital electric actuators, 16 patent for utility model.

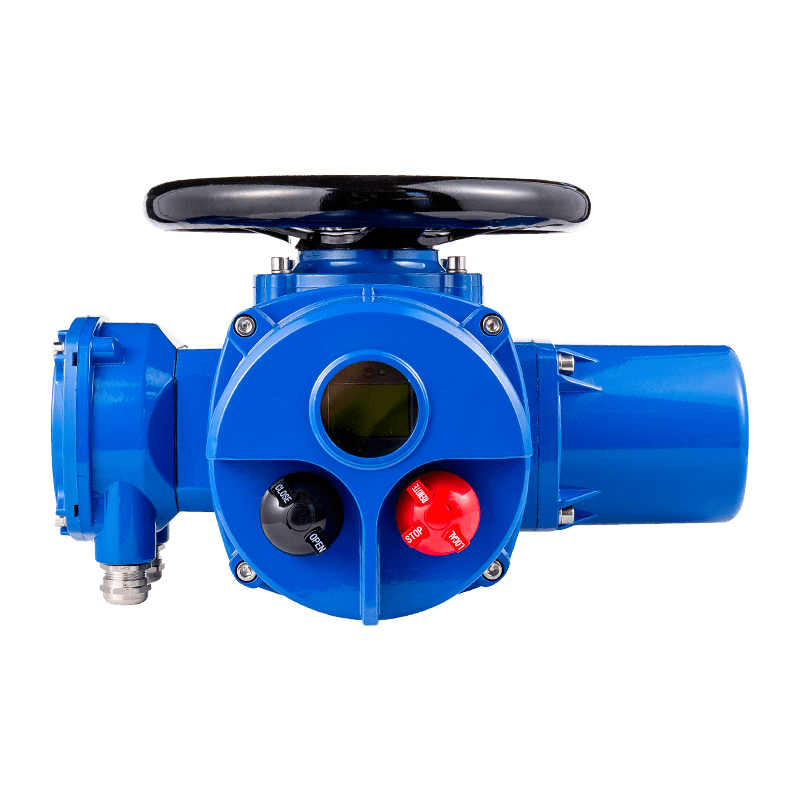

The company product series is complete, the actuator product has the common type, the whole type, the adjustment type, the intelligent type, the explosion-proof type BT4, CT4, MA mining type, and so on. The AUKEMA intelligent electric actuator has reached the international level, with better control than imported products, and is closer to the actual needs of the domestic market.

The company is committed to product type optimization and qualitmprovement, combined with the market demand, developed a special electric valve for coal mines, the application of thousands of major coal mining groups in the mine, improved the level of coal mine automation; Environmental protection desulfurization and off-sale electric valve is widely used in the field of power stations, contributing to environmental protection. Okuma explosion-proof series BT4, CT4 electric valve is the priority brand of oil, petrochemical, natural gas, gas, and other flameproof fields. In addition, many supporting products in metallurgy, water treatment, electric power, shipbuilding, fire, and other fields, users - praise. In recent years, the company increased the development of overseas markets, products are exported to Indonesia, Pakistan, Singapore, Nigeria, Malaysia, and other countries.

Enterprises adhering to desirable product quality will occupy the market, tread the industry with advanced science and technology, improve the service system to return the customer's purpose and strive to become a flow of valve actuator manufacturing enterprises.

Quality commitment: the company's products have three guarantees, product lifetime warranty, and satisfactory after-sales service.

We strive to provide quality products and satisfactory services for the development of automation, looking forward to your sincere cooperation!

русский

русский Español

Español