How is the application effect of Multi Turn Gear Box produced by Changzhou Xinneng Automatic Control Equipment Co., Ltd. in regulating and intelligent actuators? Can it meet more sophisticated control needs?

1. Company background and product overview

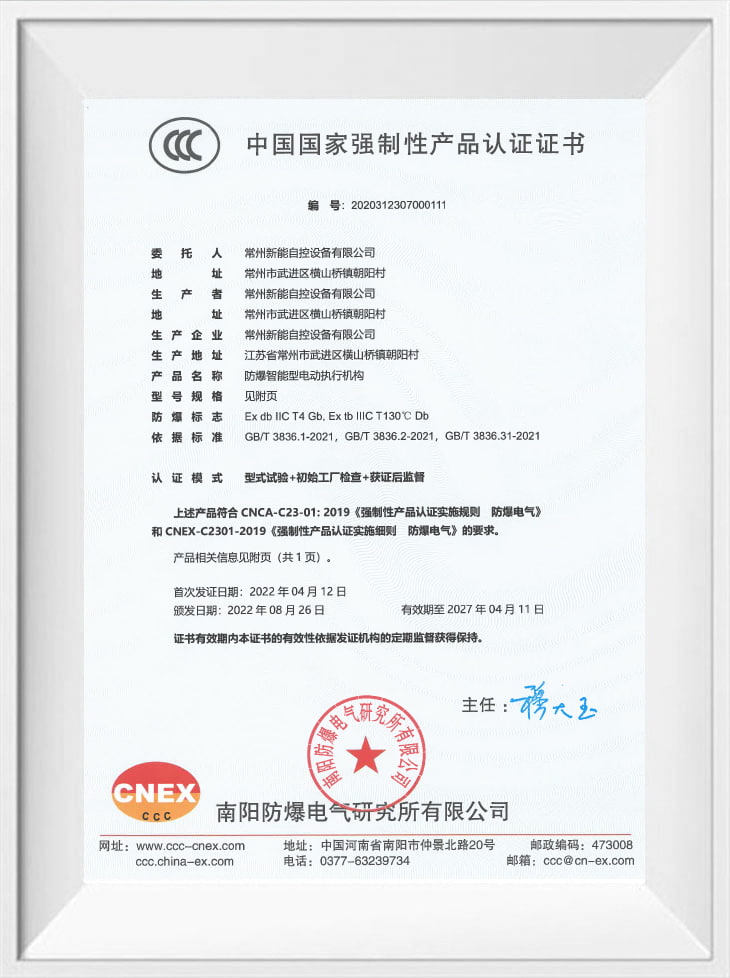

Changzhou Xinneng Automatic Control Equipment Co., Ltd. is a technology-based enterprise focusing on the research and development, production, sales and service of electric actuators, valves and automatic control systems. Since its establishment, the company has become one of the leading suppliers in the field of industrial automation at home and abroad with its strong technical research and development capabilities, rich production experience and accurate grasp of market demand. Its product series include electric valve actuators, intelligent electric actuators, Multi Turn Gear Box, etc.

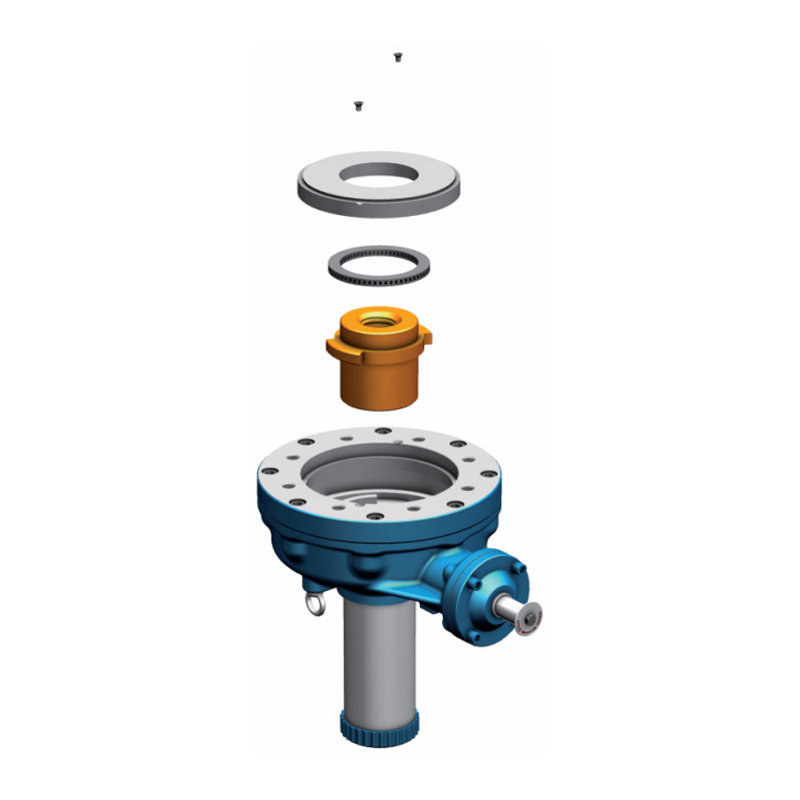

Among these products, Multi Turn Gear Box, as the core component of the actuator, carries very important functions, especially in regulating and intelligent actuators, plays a key role.

2. The application effect of Multi Turn Gear Box in regulating actuators

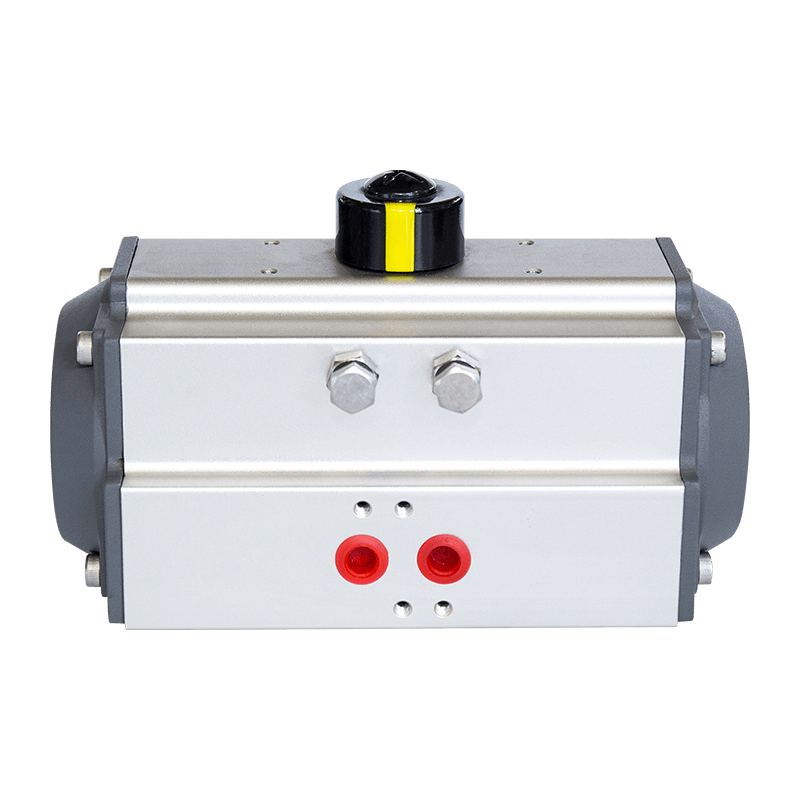

Regulating actuators are usually used in occasions where the position and action of valves or other control equipment are required to be precisely adjusted, such as flow regulation, temperature control, pressure control, etc. in automatic control systems. As one of the core components of the regulating actuator, the multi-turn gearbox has the characteristics of high efficiency, precision and durability, and is widely used in these fields.

Accurate control performance: The multi-turn gearbox can convert the rotary motion of the electric actuator into the linear displacement of the control object such as the valve. In the regulating actuator, the accuracy of the gearbox directly determines the accuracy of the system control. The multi-turn gearbox of Changzhou Xinneng Automatic Control Equipment Co., Ltd. adopts advanced gear design and high-precision processing technology to provide extremely precise motion control. During the transmission process, its gearbox can ensure smooth movement and precise positioning, significantly improving the control accuracy of the regulating actuator.

High load bearing capacity: The regulating actuator often needs to work continuously under heavy loads, especially in industrial process control, such as chemical industry, power industry and other fields. The multi-turn gearbox of Changzhou Xinneng Automatic Control Equipment Co., Ltd. is designed with high-load working environment in mind. It adopts high-strength alloy materials and combines optimized gear structure with good load-bearing capacity and stability, ensuring that there is no gear wear or failure during long-term high-load operation, thereby ensuring the long-term stable operation of the regulating actuator.

Durability and corrosion resistance: In harsh industrial environments, modulating actuators are often exposed to high temperature, high humidity, corrosive gases or liquids. The multi-turn gearbox of Changzhou Xinneng Automatic Control Equipment Co., Ltd. adopts anti-corrosion coating and high-quality anti-rust materials, which not only improves the durability of the gearbox, but also enables it to adapt to the working requirements in different environments, especially in the chemical, petroleum and other industries, with stronger environmental adaptability.

High efficiency and energy saving: The transmission efficiency of the Multi Turn Gear Box directly affects the energy efficiency and response speed of the actuator. Changzhou Xinneng Automatic Control Equipment Co., Ltd. optimizes the transmission design of the gearbox, reduces energy loss and friction, and improves the efficiency of the overall system, so that the modulating actuator can effectively reduce energy consumption while achieving high-precision control.

3. Application effect of multi-turn gearbox in intelligent actuator

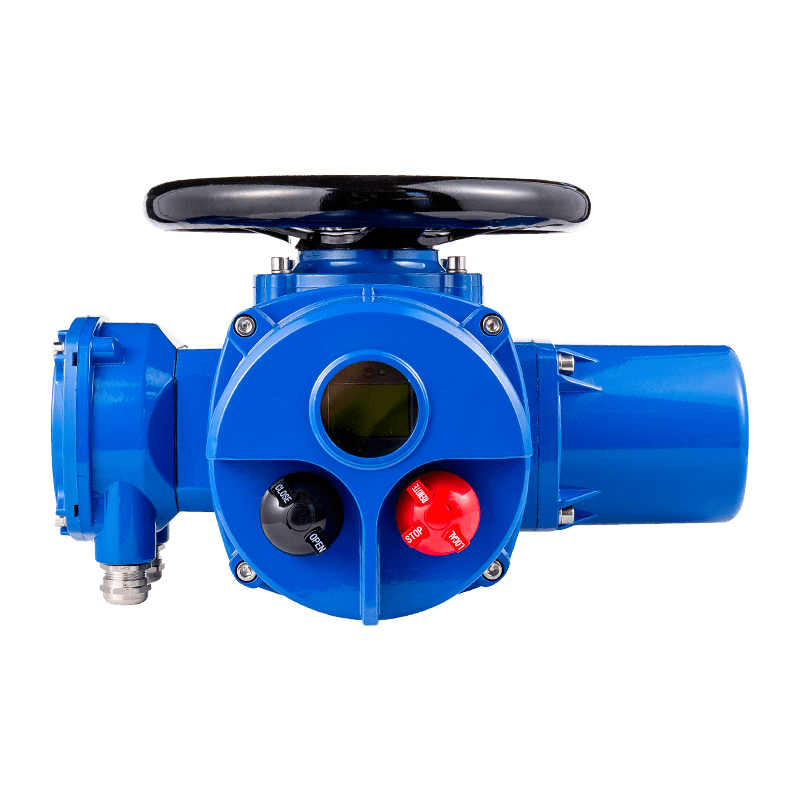

Compared with traditional actuators, intelligent actuators have a higher degree of automation and stronger intelligent control functions. It can exchange real-time data with the control system through sensors and communication modules, and automatically adjust actions according to environmental changes and control requirements. The application of multi-turn gearboxes in intelligent actuators requires them to have higher integration and stronger adaptability to meet the precise control requirements of intelligent control systems.

Intelligent integration: Intelligent actuators need to realize functions such as real-time data feedback, parameter adjustment and remote control with the control system. The company's multi-turn gearbox can be perfectly combined with intelligent electric actuators, and realize data transmission and fault diagnosis through the built-in intelligent control module. The high-efficiency drive system designed inside its gearbox can quickly respond to intelligent control instructions to ensure that the entire actuator can quickly and accurately complete rotation or position adjustment after receiving the control signal.

Adaptive adjustment: Intelligent actuators often need to automatically adjust control parameters according to different system requirements. The company's multi-turn gearbox can cooperate with intelligent actuators to achieve adaptive adjustment. During the control process, it can automatically adjust according to load changes and working conditions in real time to ensure the optimal operation of the system. For example, during the flow adjustment process, the intelligent actuator can automatically detect flow changes and adjust the valve position, while the multi-turn gearbox provides stable mechanical transmission to ensure a smooth and unimpeded adjustment process.

High precision and high frequency response: Intelligent actuators usually require high-frequency precision adjustment. The company's Multi Turn Gear Box has been precisely designed to maintain accuracy and stability under high-frequency operation. Its unique gear system and lubrication design can effectively reduce mechanical vibration and transmission errors, ensuring that the intelligent actuator can still maintain high-precision control during rapid adjustment, meeting higher-demand adjustment applications such as HVAC systems, precision instrument control, etc.

Intelligent fault diagnosis and self-repair function: As an important part of the intelligent actuator, the company's multi-turn gearbox is equipped with self-monitoring and fault diagnosis functions, which can monitor the operating status of the actuator in real time. When the system is abnormal, the gearbox will feedback the abnormal information to the intelligent control unit through the built-in sensor, trigger an early warning and start the self-repair function, thereby ensuring stable operation of the system and reducing maintenance costs.

русский

русский Español

Español