0086 15335008985

Why is the multi turn valve electric device so important in industrial automation?

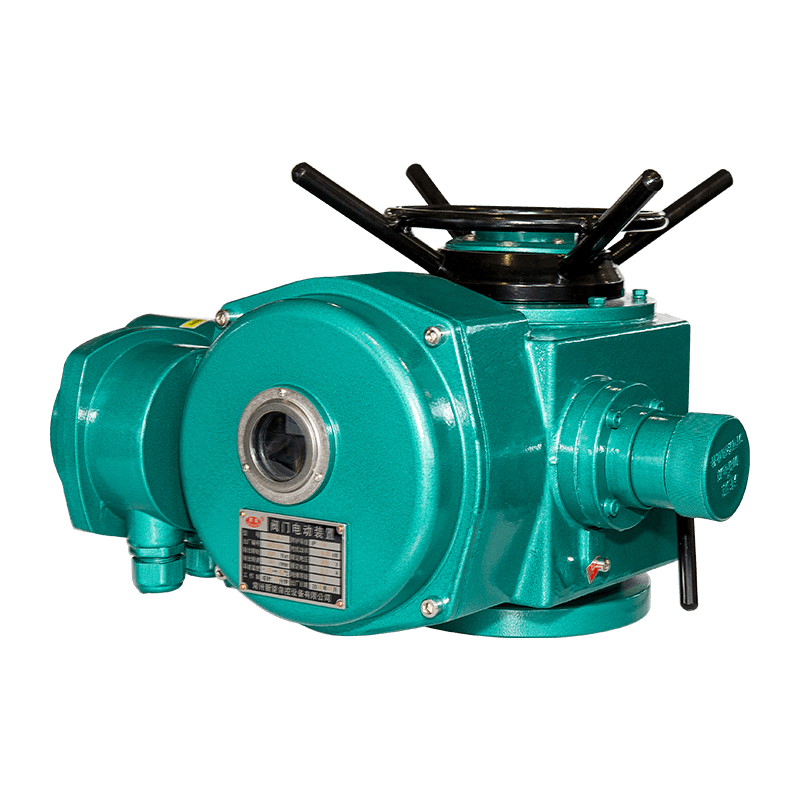

In the industrial automation system, the multi turn valve electric device is the core driving device for controlling the delivery of fluid media. Its continuous rotation capability of more than 360 degrees makes it an ideal partner for gate valves, stop valves and other valves that require multiple rotations. This type of device integrates mechanical structure and intelligent control technology to build a stable and reliable automation control link in various industrial scenarios. Its design concept and functional characteristics have a profound impact on the efficiency and safety of industrial production.

Cooperative design of intelligent core and drive system

The intelligent characteristics of the multi turn valve electric device are derived from its ultra-large-scale integrated circuits. This core component gives the device powerful data processing and instruction parsing capabilities. The intelligent controller is compatible with standard analog current signals, switch signals and multiple bus protocols, and can receive the control system’s instructions in real time and accurately convert them into valve action parameters. Matched with the intelligent core is its three-phase asynchronous motor drive system. The motor forms a power transmission chain with the hollow output shaft through the worm gear reducer.

The characteristics of the three-phase asynchronous motor enable it to maintain stable output power under small voltage fluctuations, while the deceleration and torque-increasing effect of the worm gear reducer can convert the high-speed rotation of the motor into a large torque motion of the output shaft. This combination meets the power requirements for valve opening and closing. Through the self-locking function of the reducer, the valve position is firmly locked when the power is off or shut down, avoiding valve malfunction caused by medium pressure shock, and providing basic protection for production safety.

Industrial adaptability of operation mode and protection design

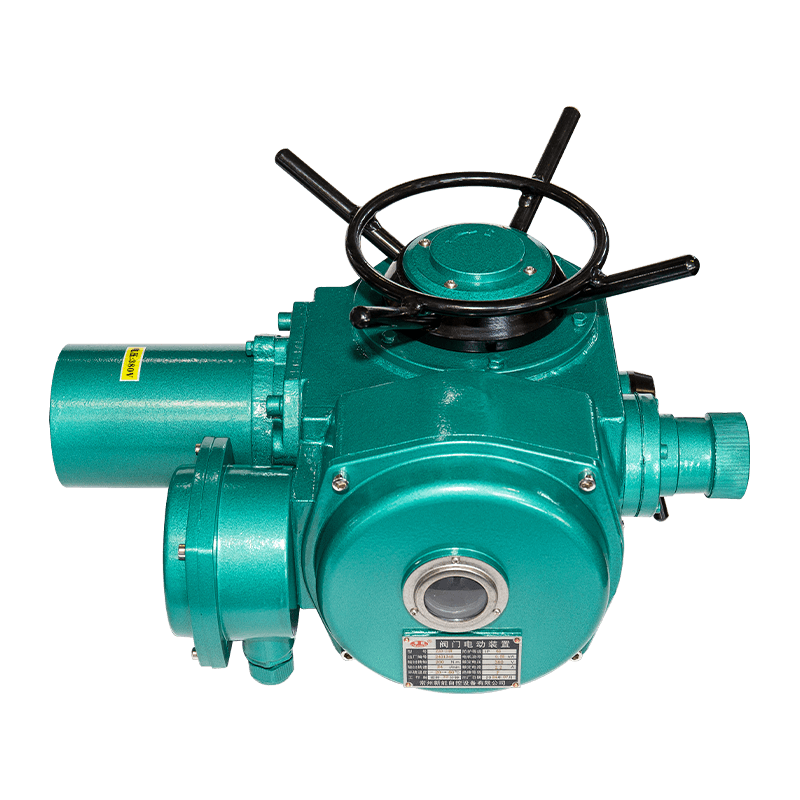

The manual and electric dual-mode switching mechanism is the key design of the multi turn valve electric device to adapt to complex industrial environments.

In the electric mode, the device can realize unattended operation through the remote control center. In the oil pipeline transportation system, the dispatcher can centrally control the valves along the line through the SCADA system; when encountering sudden power outages or control system failures, after switching to manual mode, the operator can directly drive the valve through the handwheel to ensure that basic production scheduling can be maintained in an emergency. This switching process does not require tool assistance.

The mechanical linkage design inside the mechanism will automatically disengage from the manual transmission link when the electric command is triggered to avoid motion interference between the two modes. The non-invasive design of the device further enhances its environmental adaptability.

The double seal structure and the shell non-through shaft design form a double protective barrier. The outer seal adopts a composite structure of oil-resistant rubber and metal skeleton, which can resist the erosion of dust and water vapor; the inner seal is realized by precision-machined metal contact surface, which effectively blocks the penetration of corrosive gas or liquid. This design enables it to operate stably for a long time in humid sewage treatment plants, dusty cement plants and coastal high salt fog environments.

Practical logic of safety mechanism and function expansion

The torque protection system is the core line of defense for multi turn valve electric device to ensure equipment safety. The mechanical torque protection device monitors the load change of the output shaft through the spring and cam structure. When the torque of the valve exceeds the preset threshold due to medium crystallization, foreign body jamming and other reasons, the cam will trigger the limit switch to cut off the motor power supply and send an alarm signal to the control system. This purely mechanical response method does not rely on electronic components and can still work when the controller fails.

The multifunctional expandability of the device is reflected in its modular design. By matching with an electric drive, the adjustability of power output can be enhanced to meet the speed requirements under different load conditions; when combined with a position transmitter, the real-time valve opening can be converted into an electrical signal and fed back to the control system to form a complete closed-loop control circuit.

By adding a first-stage reducer, the multi-turn actuator can be flexibly converted into an angular stroke or linear stroke actuator. The angular stroke mode is suitable for valves such as ball valves and butterfly valves that require 90-degree rotation, while the linear stroke mode is suitable for equipment such as control valves that require linear motion.

русский

русский Español

Español