0086 15335008985

How does a quarter-turn gearbox achieve efficient torque amplification and self-locking function?

Torque amplification: the mechanical logic of transmission ratio design

The torque amplification function of a quarter-turn gearbox is based on the transmission ratio design of the worm and worm gear. Its core formula is:

Output torque = input torque × transmission ratio

The transmission ratio is determined by the number of worm heads (Z1) and the number of worm gear teeth (Z2):

Transmission ratio i = Z2 / Z1

For example, when the number of worm heads is 1 (single-start worm) and the number of worm gear teeth is 50, the transmission ratio is 50:1, and the input torque of 50N·m can be amplified to 2500N·m. By adjusting the number of worm gear teeth, the torque amplification range of 5:1 to 100:1 can be flexibly achieved.

Engineering practice of transmission ratio design

Small transmission ratio (5:1-20:1): suitable for light load conditions such as valves and gates, which need to take into account transmission efficiency and response speed.

Large transmission ratio (20:1-100:1): used in heavy-load scenarios such as cranes and winches, and the bearing capacity of worm gears needs to be enhanced.

For example, in the valve control of nuclear power plants, the gearbox needs to withstand the impact of high-temperature and high-pressure media. The large transmission ratio design can ensure the precise control of valve opening and closing.

Self-locking function: the mechanical principle of helix angle optimization

1. The mechanical nature of self-locking characteristics

The self-locking function of worm gears originates from the relationship between the helix angle (λ) and the friction angle (φ). When the helix angle is smaller than the friction angle, the worm wheel cannot reverse drive the worm, forming self-locking. Its mathematical expression is:

λ < φ

The friction angle is determined by the material friction coefficient (μ):

φ = arctan(μ)

For example, the friction coefficient of bronze worm gears and steel worms is about 0.1, corresponding to a friction angle of 5.7°, so the helix angle needs to be smaller than this value to achieve self-locking.

2. Engineering application of self-locking function

Anti-reverse protection: In scenes such as elevators and cranes, the self-locking function can prevent the load from moving in the opposite direction due to gravity or external forces, thus avoiding accidents.

Improved positioning accuracy: In CNC machine tools and robot joints, the self-locking feature can eliminate transmission clearance and improve positioning accuracy to ±0.01mm.

For example, in the ship steering system, the self-locking function of the gearbox can ensure that the rudder blade remains stable in harsh sea conditions and avoids yaw.

Innovation in materials and processes: support for high-efficiency transmission

1. Worm material: quenching process of high-strength alloy steel

As the core component of torque transmission, the worm needs to withstand high stress and wear. The typical material is 40CrNiMoA, which can reach a hardness of 58-62HRC after quenching treatment and a tensile strength of more than 1000MPa. The quenching process forms a martensitic structure through rapid cooling, which significantly improves the hardness and wear resistance of the material.

2. Worm gear material: shock-absorbing properties of bronze alloy

The worm gear material needs to take into account both wear resistance and shock absorption. Tin bronze (ZCuSn10Pb1) is the first choice due to its high tensile strength (≥300MPa) and low friction coefficient (0.05-0.1). Its shock absorption characteristics are derived from the plastic deformation ability of the copper matrix, which can absorb impact energy and reduce vibration noise.

3. Process innovation: synergistic optimization of grinding and lubrication

Worm grinding: CBN grinding wheel is used for superfine grinding, and the tooth surface roughness Ra≤0.4μm ensures meshing accuracy.

Lubrication system: Through the combination of oil mist lubrication and forced lubrication, a stable oil film is formed to reduce the friction coefficient to below 0.03.

For example, in wind power gearboxes, the lubrication design of worm gears can increase the transmission efficiency to more than 97%.

Application scenarios: from industrial valves to high-end equipment

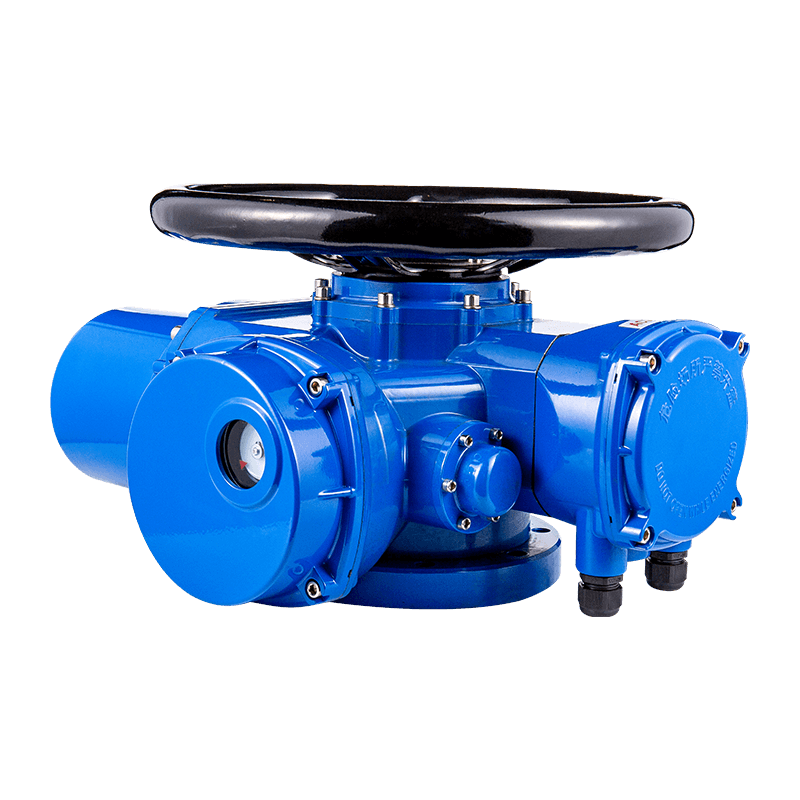

1. Industrial valve control

In industries such as petroleum, chemical, and electric power, valves driven by quarter-turn gearboxes must withstand the impact of high-temperature and high-pressure media. Its torque amplification function ensures that the valve opens and closes quickly, and its self-locking characteristics prevent the medium from flowing back. For example, in the cooling water system of a nuclear power plant, the gearbox needs to operate stably at a high temperature of 300°C.

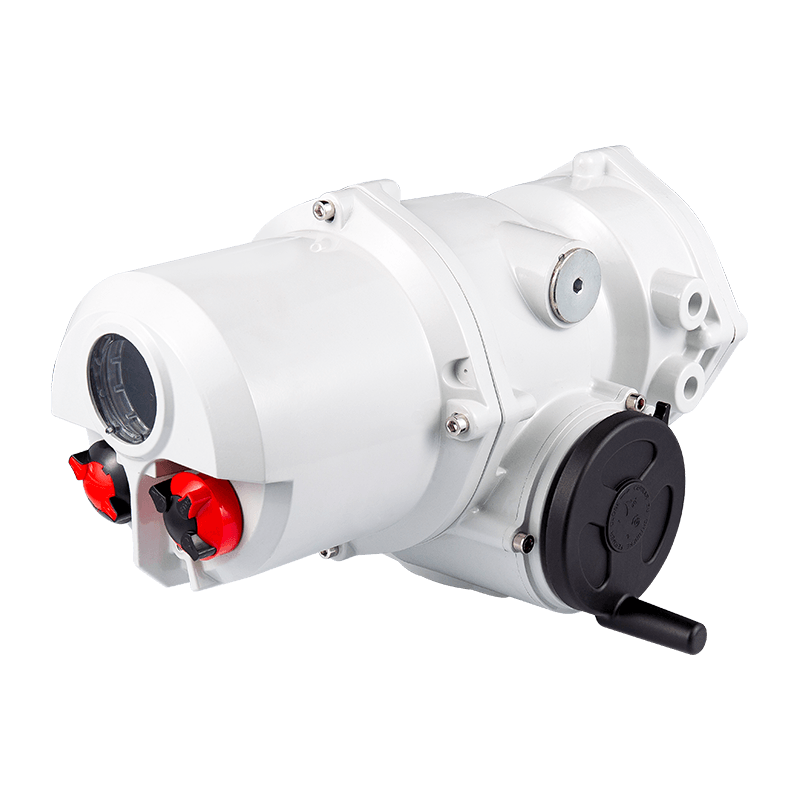

2. Heavy-duty transmission system

In cranes, winches and other scenarios, the gearbox needs to withstand loads of tens of tons. Its large transmission ratio design can amplify the motor torque to thousands of Newton meters, and the self-locking function prevents the load from accidentally falling. For example, in port cranes, the life of the gearbox needs to exceed 10 years.

3. High-end equipment field

In fields such as aerospace and robotics that require extremely high precision and reliability, the self-locking characteristics and positioning accuracy of the gearbox become key. For example, in satellite attitude control systems, the gearbox needs to maintain a positioning accuracy of ±0.001° in a vacuum environment.

русский

русский Español

Español