0086 15335008985

How do you maintain a Q-type partial rotary valve electric device for optimal performance?

Maintaining a Q-type partial rotary valve electric device is essential for ensuring long-term reliability, efficiency, and safety in industrial applications. Proper maintenance not only extends the lifespan of the device but also minimizes downtime and operational disruptions.

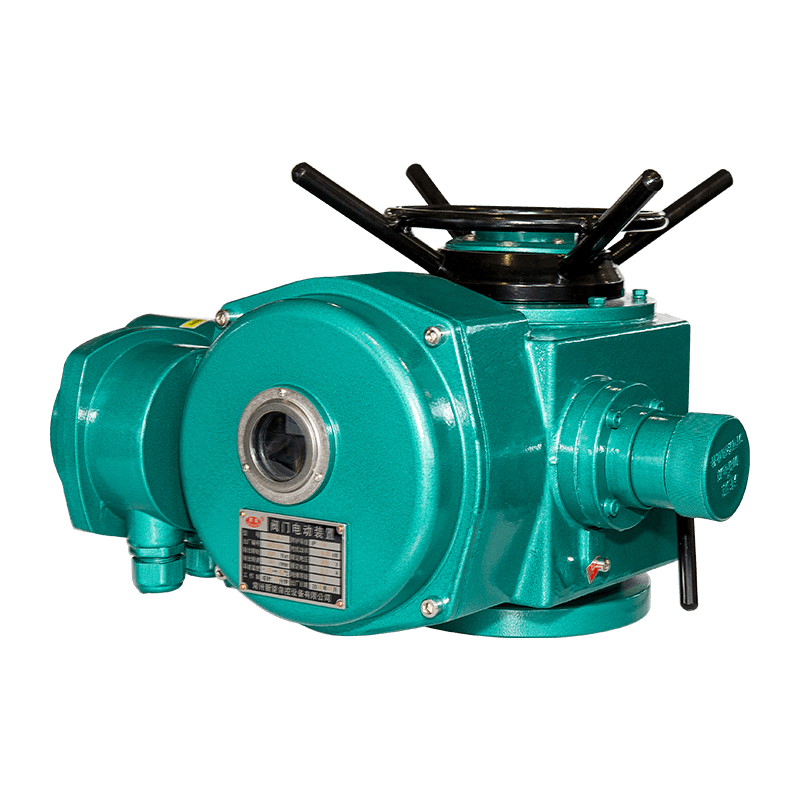

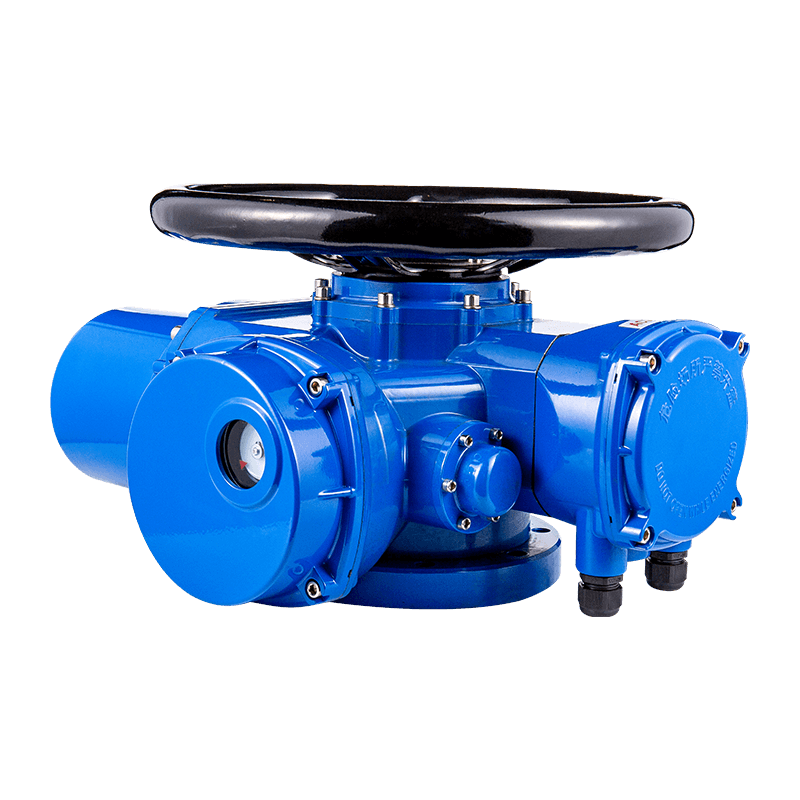

Understanding the Q-type partial rotary valve electric device

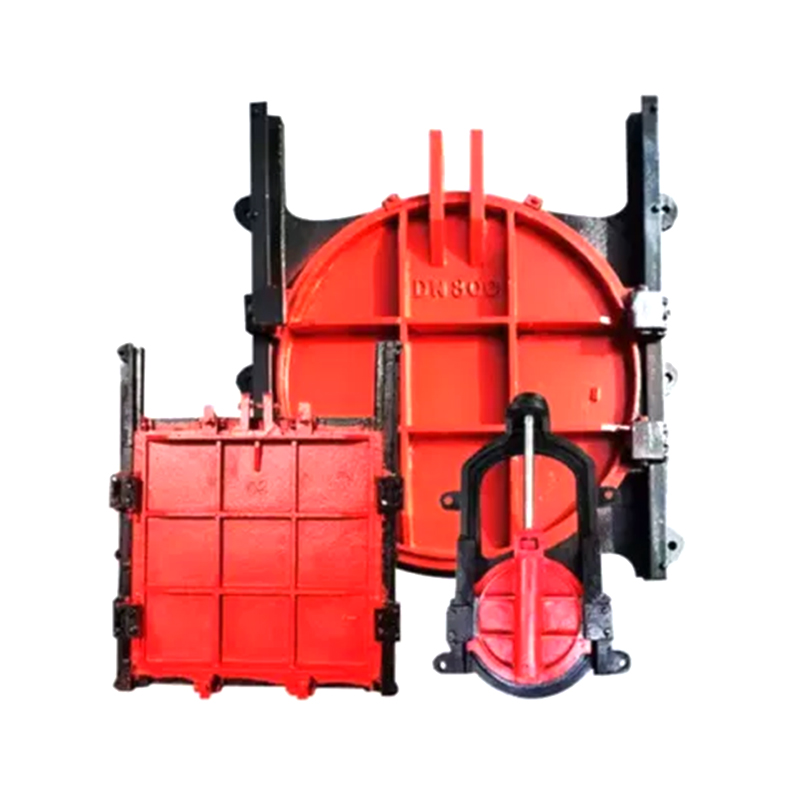

The Q-type partial rotary valve electric device is commonly used in process control systems to regulate fluid flow with precision. Its design allows for partial rotation, typically between 90° and 180°, making it suitable for applications requiring fine adjustments. Since the device integrates mechanical and electrical components, maintenance must address both aspects to prevent failures.

Routine inspection and cleaning

Regular visual inspections are the first step in maintaining a Q-type partial rotary valve electric device. Operators should check for signs of wear, corrosion, or leakage around the valve body and actuator. Dust, debris, or chemical residues can impair movement, so cleaning the exterior with a soft brush or cloth is recommended. If the device operates in a harsh environment, more frequent inspections may be necessary.

Internal components, such as gears and seals, should also be examined periodically. Any buildup of contaminants inside the valve can lead to sticking or erratic operation. Non-invasive inspection methods, such as borescopes, can help assess internal conditions without disassembly.

Lubrication of mechanical components

Proper lubrication is critical for smooth operation. The Q-type partial rotary valve electric device contains moving parts that require the correct type and amount of lubricant. Over-lubrication can attract dirt, while under-lubrication increases friction and wear. Manufacturers typically specify the appropriate lubricant and intervals for application.

Key lubrication points include:

- Gear mechanisms – Ensures smooth rotation.

- Stem and bearing surfaces – Reduces friction and prevents seizing.

- Seals and O-rings – Maintains flexibility and prevents leaks.

A lubrication schedule should be documented and followed strictly to avoid premature failure.

Electrical system maintenance

Since the Q-type partial rotary valve electric device includes an electric actuator, electrical maintenance is equally important. Terminal connections should be checked for tightness and corrosion, as loose or corroded contacts can lead to power fluctuations or failure. Wiring insulation must be inspected for cracks or fraying, especially in high-temperature or humid environments.

The actuator’s motor and control circuitry should undergo periodic testing to ensure proper functionality. If the device uses position feedback sensors, calibration checks should be performed to confirm accurate valve positioning. Any deviations in electrical performance should be addressed immediately to prevent operational issues.

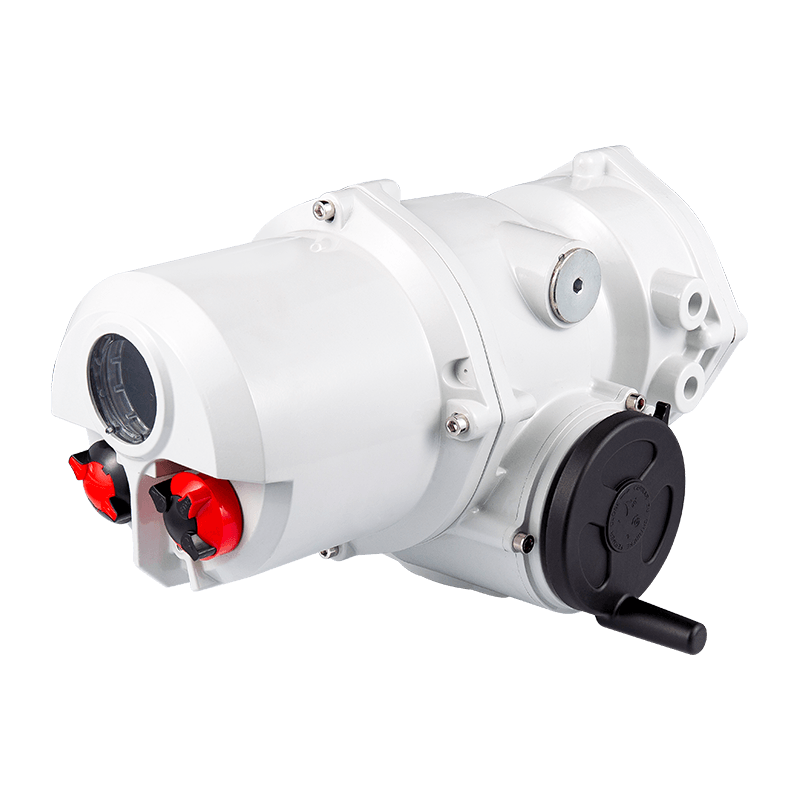

Environmental considerations

The operating environment significantly impacts the longevity of a Q-type partial rotary valve electric device. Exposure to extreme temperatures, moisture, or corrosive substances can accelerate wear. Protective measures, such as weatherproof enclosures or corrosion-resistant coatings, may be necessary in harsh conditions.

If the device is installed outdoors, UV-resistant covers can prevent degradation from sunlight. In dusty or abrasive environments, air purging systems or protective boots may help keep contaminants away from critical components.

Troubleshooting common issues

Even with proper maintenance, issues may arise. Some common problems and their solutions include:

| Issue | Possible cause | Recommended action |

|---|---|---|

| Valve not rotating | Power supply failure | Check voltage and connections |

| Erratic movement | Contaminated lubrication | Clean and re-lubricate |

| Excessive noise | Worn gears or misalignment | Inspect and replace damaged parts |

| Leakage | Damaged seals or gaskets | Replace faulty seals |

Preventive maintenance is always preferable to reactive repairs. Keeping detailed logs of inspections, lubrication, and part replacements helps identify patterns and predict potential failures before they occur.

Maintaining a Q-type partial rotary valve electric device requires a systematic approach that includes regular inspections, proper lubrication, electrical checks, and environmental protection. By following these guidelines, operators can ensure optimal performance, reduce downtime, and extend the service life of the device. Consistency in maintenance practices is key to avoiding unexpected failures and maintaining efficient process control.

русский

русский Español

Español